How to Weld Plastic to Plastic

Publish Data:2025.7.15 Author: Hyusonic

Plastic-to-plastic welding is an essential technique in various industries, from automotive manufacturing to consumer electronics. If you’ve ever wondered how to weld plastic to plastic, you’re not alone. This comprehensive guide will take you through the fundamentals and advanced methods, helping you master how to plastic weld, whether you’re a seasoned professional or a DIY enthusiast.

Understanding the Basics of Plastic to Plastic Welding

Before diving into specific methods, it’s important to understand what plastic welding entails. The process typically involves heating the surface of two plastic parts until they melt and fuse together under pressure. Key factors include applying the right amount of heat, pressure, and time. Different plastics—especially those reinforced with fiberglass or other additives—require customized welding approaches.

Fiberglass-reinforced plastics, for instance, have different melting points and thermal conductivities compared to pure thermoplastics. These properties demand precise control during the welding process to avoid weak joints or material degradation.

Common Methods for Plastic to Plastic Welding

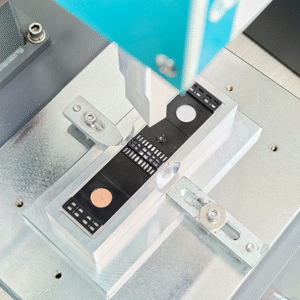

An Ultrasonic welder uses high-frequency mechanical vibrations to generate heat at the joint interface. This method is fast, clean, and highly effective for small and medium-sized parts. It works exceptionally well even with fiberglass-filled plastics, as the ultrasonic energy can overcome the insulating effect of the filler.

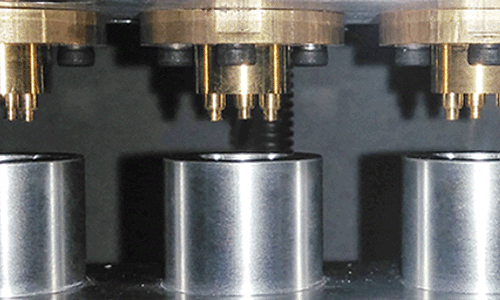

2. Heat Staking

A Heat staking machine uses a heated metal tool (called a stake) to melt and reshape a plastic boss or stud over another plastic part, effectively “riveting” the parts together. This method is suitable for joining dissimilar plastics and works well when dealing with inserts or components of different shapes and sizes.

3. Hot Plate Welding

A Hot plate machine melts the surfaces of both plastic parts using a heated plate. Once the surfaces are soft, the plate is removed, and the parts are pressed together. It’s ideal for larger parts or complex geometries, especially when welding composite or reinforced plastics that require longer heating times.

4. Spin Welding / Friction Welding

Spin welding joins circular plastic parts by rotating one against the other under pressure. The friction generates heat to melt the contact surfaces. It’s a great method for cylindrical components like tanks or containers.

5. Laser Welding

Laser welding uses focused laser energy to melt plastics along a seam. This highly precise method is well-suited for cleanroom environments or microcomponents and can weld transparent and opaque plastics with special absorption layers.

6. Hot Air Welding

Hot air welding (also called hot gas welding) involves using a stream of heated air to soften the surfaces and a filler rod, similar to metal welding. It’s popular for sheet plastic, pipes, and fabrication of large panels.

Welding Between Different Plastics

Welding dissimilar plastics is inherently more challenging. Generally, plastics with similar molecular structures and melting points are more compatible. For example:

PE (Polyethylene) to PE: Easy and strong weld

PP (Polypropylene) to PP: Also straightforward

PE to PP: Difficult, requires additives or specialty processes

Nylon to ABS: Usually incompatible without a third agent

For fiberglass-reinforced plastics, ensure the base resin type matches or that the welding method compensates for the additional thermal insulation caused by the filler.

Tip: Always test weld compatibility before full-scale production.

Tips for Successful Plastic Welding

Clean Surfaces: Dirt or oils can compromise the weld

Alignment Matters: Misalignment reduces strength

Test Before Production: Especially important with composites

Monitor Temperature and Pressure: Too much or too little can ruin the joint

Practice Makes Perfect: Especially with manual methods like hot air welding

Common Troubleshooting

Weak Welds: Increase temperature or extend heating time

Cracking Post-Weld: Caused by cooling too fast or material incompatibility

Burnt Plastic: Lower the temperature or reduce pressure

Vibration Transfer Issues (Ultrasonic): Adjust amplitude to match material density, especially for fiberglass-filled parts

Recommended Machines

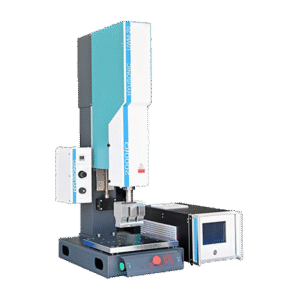

Ultrasonic Plastic Welding Machine 2000iQ Series

- 6 welding modes, 5 triggering methods

- Simple operation, high yield,

- Suitable for most thermoplastics

- Servo control, excellent precision

- Instant cooling and heating to improve efficiency

- Use on metal or plastic, various materials

Conclusion

Knowing how to weld plastic to plastic opens a wide range of possibilities in manufacturing, repair, and product design. Whether you’re exploring how to plastic weld for the first time or upgrading your production line, choosing the right method—be it ultrasonic, hot plate, or heat staking—makes all the difference. Don’t forget the critical importance of material compatibility, especially with fiberglass or other composite-filled plastics. With the proper tools, techniques, and practice, you can achieve professional-grade plastic-to-plastic welding results.

Hyusonic is a Chinese manufacturer with 20 years of experience in plastic welding. We independently develop and design all levels of ultrasonic welding machines, hot riveting machines, rotary friction welding machines, and hot plate welding machines. Contact us to customize your machine and get a quick quote.