Near-Field vs. Far-Field Ultrasonic Welding: Key Differences and Applications

Publish Data:2025.7.16 Author: Hyusonic

Ultrasonic plastic welding has become a critical joining technique in modern manufacturing, enabling fast, clean, and reliable bonding of thermoplastics without adhesives or screws. Within ultrasonic welding, two primary configurations exist: Near-Field Welding and Far-Field Welding. Understanding the difference between these two methods is essential when choosing the right process for your plastic assembly application.

In this guide, we’ll break down the key distinctions between Near-Field and Far-Field ultrasonic welding, explore their advantages, limitations, and use cases, and help you determine which is best for your project.

What Is Near-Field Ultrasonic Welding?

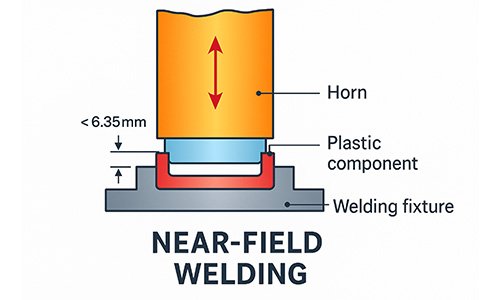

Near-field welding occurs when the ultrasonic horn (sonotrode) is placed in direct contact or very close to the plastic parts being joined. The energy travels only a short distance—typically less than 6 mm (0.25 in)—from the horn to the weld joint.

Characteristics:

Direct horn-to-part contact

Short energy path

High-frequency vibration transfer

Ideal for small, precise components

Typical Applications:

Medical devices (catheters, valves)

Electronic components (USB housings, sensors)

Microfluidic parts

Consumer product enclosures

What Is Far-Field Ultrasonic Welding?

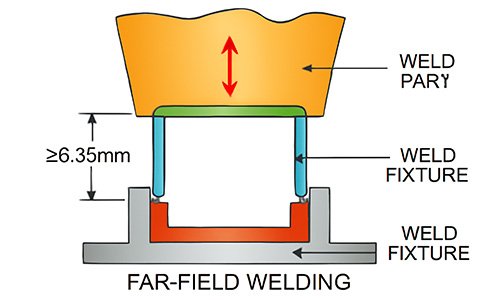

Far-field welding, in contrast, is used when the horn is located farther from the weld joint—often more than 6 mm. The ultrasonic vibrations must travel through a larger mass of plastic to reach the joint.

Characteristics:

Indirect horn placement

Energy passes through the plastic body

Requires rigid, low-damping materials

Better suited for larger, uniform parts

Typical Applications:

Automotive components (dashboards, HVAC parts)

Appliance housings

Larger electronic devices

Key Differences: Near-Field vs. Far-Field Welding

| Feature | Near-Field Welding | Far-Field Welding |

|---|---|---|

| Horn Placement | Direct or very close to joint | Distant from joint |

| Energy Travel Distance | < 6 mm (short) | > 6 mm (long) |

| Material Requirements | Most thermoplastics | Rigid, low-attenuation plastics only |

| Part Size | Small to medium components | Medium to large components |

| Weld Precision | High | Moderate |

| Design Flexibility | Less restrictive | Requires robust, symmetric design |

| Typical Industries | Medical, Electronics, Consumer Goods | Automotive, Appliances, Heavy-Duty Electronics |

Advantages and Limitations

Near-Field Welding – Pros:

High precision and control

Fast cycle time

Strong welds with minimal energy loss

Less sensitive to part geometry

Cons:

Limited to smaller parts or close-access weld joints

Far-Field Welding – Pros:

Suitable for larger assemblies

Allows tool placement away from weld zone

Less wear on horn due to non-contact design

Cons:

Energy loss over distance

Not suitable for soft or highly attenuative plastics

Requires careful design and fixturing

Design Considerations for Each Method

For Near-Field Welding:

Design parts with easy access to the joint

Include energy directors to improve weld consistency

Avoid soft or very thin materials near horn contact area

For Far-Field Welding:

Ensure parts are rigid and symmetric to reduce vibration loss

Use consistent wall thickness

Materials should transmit ultrasonic energy effectively (e.g., ABS, PC, PMMA)

Choosing the Right Method

To determine which welding method is best for your project, consider the following:

Component size: Use Near-Field for micro or compact parts; Far-Field for large or deep assemblies.

Material type: Far-Field requires rigid, low-damping thermoplastics.

Weld location: Near-Field is best when joints are accessible; Far-Field works when joints are embedded or hard to reach.

Production scale: Both methods support high-volume manufacturing, but Near-Field generally allows tighter quality control.