Ultrasonic Sealing vs Heat Sealing: Choosing the Right Technology for Your Packaging Needs

Publish Data:2025.7.22 Author: Hyusonic

In the competitive world of packaging machinery, understanding the nuances between ultrasonic sealing vs heat sealing is crucial. Manufacturers must evaluate throughput, energy consumption, seal integrity, and material compatibility before investing in equipment such as a vacuum heat sealing machine, ultrasonic sealing machine, or an RF heat sealing machine.

Fundamental Principles

Heat Sealing

Traditional heat sealing devices rely on heated bars or jaws to melt thermoplastic films. A heat and seal machine raises film temperature above its melting point and then applies pressure until the molten layers fuse and cool. Common variants include the plastic heat sealing machine and the heat seal plastic pouchers used in food packaging.Ultrasonic Sealing

Ultrasonic sealer technology uses a vibrating horn to generate high-frequency energy. This localized vibration creates molecular friction at the interface, instantly welding plastics without external heat. Often branded as a sonic seal or radio frequency heat seal (in some hybrid designs), pure ultrasonic systems avoid the drawbacks of thermal inertia.

Equipment Types and Applications

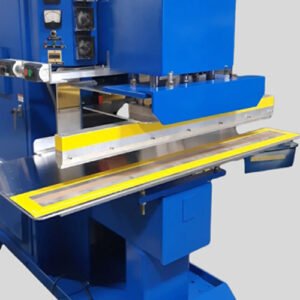

Vacuum Heat Sealing Machine

Integrates vacuum chambers with heat sealing jaws. Ideal for perishable foods, it evacuates air before sealing, extending shelf life. However, warm-up times and continuous power draw remain unavoidable.RF Heat Sealing Machine

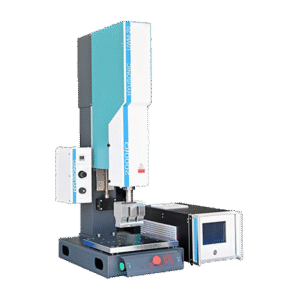

Employs radio frequency energy to excite polar molecules within packaging films. Known as a radio frequency heat seal, it works well with PVC and certain multi-layers but demands specialized rf heat sealing oscillators and electrode assemblies.Ultrasonic Sealing Machine

A dedicated ultrasonic sealing machine or ultrasonic welder excels at rapid, narrow welds. It’s highly effective on polyethylene, polypropylene, and biopolymers used in medical and food-grade films.

Energy Efficiency and Throughput

Energy consumption differentiates these systems sharply:

Heat and Seal Machine

Requires several minutes of warm‑up and maintains bars at 150–200 °C, leading to continuous high power draw, even between cycles.Ultrasonic Sealer

Activates electrical power only during the weld cycle, typically 0.05–0.2 s per seal. Benchmarks show up to 60% reduction in energy usage compared to a heat sealing machine of similar output.

Hybrid sonic seal units—combining ultrasonic and heat methods—attempt compromise but often inherit drawbacks from both technologies.

Seal Quality and Material Waste

Seal Width

Heat seals usually span 8–12 mm, while ultrasonic welds can be as narrow as 2–3 mm. Narrow welds on an ultrasonic sealing machine translate into significant film savings—up to 70% less scrap over large runs.Contamination Tolerance

A heat sealing device struggles when crumbs, powders, or liquids are present in the sealing zone, causing leaks. In contrast, ultrasonic vibrations can “cut through” light contamination, producing a hermetic seal.Product Safety

Heat-sensitive contents like chocolates, cheeses, or pharmaceuticals can degrade or discolor under prolonged bar contact. Ultrasonic sealing avoids bulk heating, safeguarding product integrity.

Maintenance and Lifecycle Costs

Plastic Heat Sealing Machine

Maintenance involves replacing Teflon tape on bars and occasional heater cartridges. Downtime for cooling and tape changes reduces effective throughput.Ultrasonic Sealing Machine

With no heating elements or tapes, upkeep is limited to occasional inspection of the horn, anvil, and generator electronics. Total cost of ownership studies show payback periods under 12 months when retrofitting high‑volume lines.RF Heat Sealing Machine

Requires periodic checks of RF generators and electrode surfaces. Misaligned electrodes can cause uneven seals or arcing damage.

Application Scenarios

| Scenario | Recommended Technology |

|---|---|

| High‑speed snack bag lines | Ultrasonic Sealer |

| Vacuum‑packed meats & cheeses | Vacuum Heat Sealing Machine |

| PVC pouching (medical devices) | RF Heat Sealing Machine |

| Biodegradable film packaging | Ultrasonic Sealing Machine |

| Bulk heavy‑duty sacks | Plastic Heat Sealing Machine |

Key Takeaways

Ultrasonic Sealing vs Heat Sealing: For minimal waste, rapid cycles, and precise bonds, ultrasonic wins.

Vacuum Heat Sealing Machine: Best when product life extension via vacuum is paramount.

RF Heat Sealing: Suited to polar polymer films but entails higher equipment complexity.

Sonic Seal hybrids mix both worlds but rarely outperform dedicated systems.

Seal Integrity: Ultrasonic sealers excel at overcoming contamination.

Case Study: Sunray Food Packaging Upgrade

Background:

Sunray (a division of Swiss retailer Coop) struggled with high reject rates on its HFFS line when packaging powdered mixes. Heat sealing at 60 bags/min failed under light dust and humidity, causing frequent leaks.

Solution:

In 2020, Sunray replaced the heat seal unit with a Telsonic ultrasonic sealing module—no warm‑up required, and vibrations “cut through” residual powder.

Results:

Throughput +33%: Speed rose from 60 to 80 bags/min.

Defects ↓98%: Leaks and rejects were virtually eliminated.

Energy ↓20% & Maintenance ↓: Annual film and power savings of 8% and 15%, plus reduced downtime.

Conclusion

For projects demanding high throughput, low energy consumption, and precise seals, ultrasonic sealing is unquestionably superior. If extended shelf life or PVC packaging is required, vacuum heat sealing and RF heat sealing still play a role. Please choose the sealing technology that best fits your specific application to optimize both packaging cost and quality.