Spin Welding Machine Manufacturer

Looking for reliable spin welding machine manufacturers? We offer a wide selection of high-quality plastic friction welders designed for precision welding of thermoplastic parts. Whether you need a servo-controlled welder or a custom rotary welding system, we have the right solution.

Spin Welding Machine

Hyusonic provides two models of high-performance spin welding machines — a compact desktop spin welder and a floor-standing spin welding system — both engineered for efficient and reliable friction welding of thermoplastic parts.

These machines differ in size, output force, and control configuration, offering flexibility for both small-scale production and industrial-grade applications. Whether you’re welding circular plastic components in electronics, automotive, or consumer goods, Hyusonic’s spin welders deliver consistent results with high-strength bonds.

✅ Servo or Pneumatic Spin Welding Options

✅ Ideal for Round Thermoplastic Part Welding

✅ 12-Month Warranty & Technical Support

✅ CE / ISO9001 Certified Machines

Compare Our Spin Welding Machines

| Feature / Model | Desktop Spin Welding Machine | Floor-Standing Spin Welding Machine |

|---|---|---|

| Drive System | Pneumatic or Stepper Motor | Servo Motor Controlled |

| Weldable Part Diameter | Ø 10–120 mm | Ø 20–250 mm |

| Spin Speed Control | Fixed / 3-speed adjustable | Precision Digital Control (up to 3500 rpm) |

| Material Compatibility | ABS, PP, PE, PS | ABS, PP, PE, PS, Nylon, PC |

| Automation Options | Manual Load / Semi-automatic Start | Optional Auto Feeder / Custom Fixtures |

| Typical Applications | Small plastic enclosures, caps, filters | Automotive parts, larger housings, reservoirs |

| Cycle Time (per part) | 2–5 seconds | 3–6 seconds |

| Control Interface | Basic Touch Screen / Manual Buttons | Full HMI Touch Screen |

| Machine Footprint | Compact (approx. 60×50×80 cm) | Industrial size (approx. 90×70×180 cm) |

What Is Spin Welding

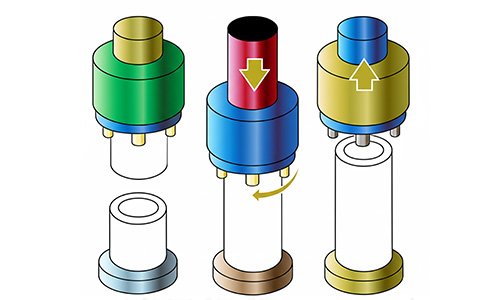

Spin welding is a friction-based process used to join thermoplastic parts. It is specifically suitable for round or cylindrical components where one part is held stationary and the other is rotated under pressure. The resulting frictional heat causes the plastic at the interface to melt and fuse together.

Working Principle

Clamping: The two plastic parts are positioned — one is clamped in place, and the other is mounted on a rotating spindle.

Rotation: The rotating part spins at a controlled speed (typically 1,000 to 3,500 RPM), generating frictional heat at the contact surface.

Melting: Once the interface reaches the melting temperature, rotation stops and pressure is maintained briefly to solidify the bond.

Cooling: The parts are held under pressure during the cooling phase, forming a strong molecular-level weld.

Why Choose Us

Direct Factory, More Reliable

As a true manufacturer, we ensure higher quality control, fast response, and professional support. Unlike traders, we offer consistent service from production to after-sales, giving clients a more stable and dependable cooperation experience.

Top Components, Global Support

We use globally trusted parts like Siemens, SMC, and etc. This ensures high machine reliability and makes local replacements easy for international users—saving time and reducing maintenance effort.

Wide Range, Transparent Pricing

From entry-level to high-end models, our ultrasonic welders suit all needs and budgets. Clear classification and pricing let customers select the right configuration with confidence and no hidden costs.

Certified & Patent-Protected Tech

Our machines are CE, ISO-certified and backed by multiple patents. With strong R&D, we deliver safe, innovative, and performance-driven solutions for demanding industries worldwide.

Your satisfaction is our goal

Professional Plastic Welding Solution Manufacturer

FAQs About Spin Welding Machines

What is a spin welding machine used for?

Spin welding machines are designed for joining circular thermoplastic parts through frictional heat generated by rotational motion. Common applications include sealing filter housings, assembling caps, reservoirs, and round enclosures in the automotive, medical, and consumer goods industries.

What materials are compatible with spin welding?

How does spin welding differ from ultrasonic welding?

Spin welding uses rotational motion to generate frictional heat, making it ideal for round parts. Ultrasonic welding uses high-frequency vibrations and is more suitable for small, flat parts or irregular shapes. Spin welding typically handles larger joints and delivers higher strength for circular geometries.

Is spin welding suitable for automation?

Yes, spin welding can be easily integrated into automated production lines. Servo-controlled systems allow precise parameter adjustment, and floor-standing machines can be customized with robotic feeders, safety enclosures, and PLC/HMI control for full automation.

What is the typical cycle time for a spin weld?

The typical cycle time ranges from 2 to 6 seconds per weld, depending on part size, material, and machine configuration. Servo-controlled models offer faster response and better repeatability for high-throughput applications.