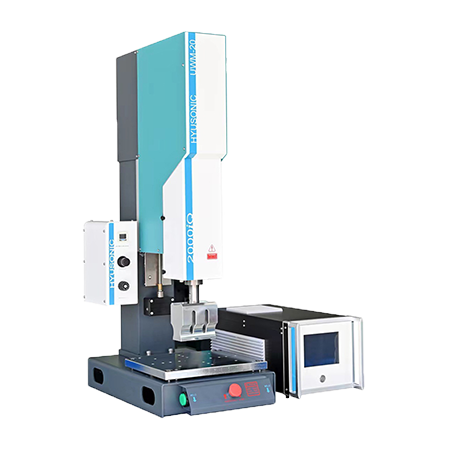

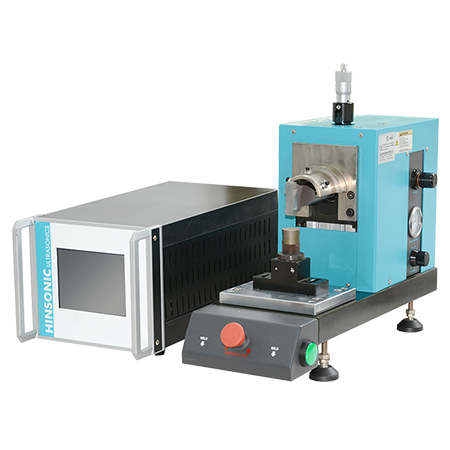

Plastic Spin Welding Machine

-

Servo-Controlled Spin System

Servo motors precisely control both spin and vertical axes to ensure consistent rotation, accurate weld depth, and strong, repeatable joints. -

Multi-Mode Welding Flexibility

Supports various weld initiation and termination modes including spin torque, vertical position, and absolute distance—ideal for a wide range of circular plastic components. -

CE & ISO 9001 Certified

Compliant with EU Machinery Directive and global quality standards for risk-free global deployment. -

Melt-Match Motion Control

Vertical axis movement can be synchronized with rotational speed to match the material’s melt rate, achieving high seal strength and tight dimensional tolerances.

description

The RW3000 Series Plastic Spin Welding Machine offers precise servo-driven control of both rotation and vertical motion, ensuring consistent welding results with minimal material distortion. It supports flexible welding modes based on torque, position, or time, adapting to a wide range of thermoplastic materials and part geometries. The machine’s synchronized axis motion enhances fusion quality, while built-in automation interfaces facilitate the easy integration of clamps, sensors, and remote triggers—eliminating the need for an external PLC. Certified to CE and ISO 9001 standards, and equipped with basic weld parameter monitoring, the RW3000 Series is a dependable choice for consistent and scalable plastic assembly.

Why Choose Us

Direct Factory, More Reliable

As a true manufacturer, we ensure higher quality control, fast response, and professional support. Unlike traders, we offer consistent service from production to after-sales, giving clients a more stable and dependable cooperation experience.

Top Components, Global Support

We use globally trusted parts like Siemens, SMC, and etc. This ensures high machine reliability and makes local replacements easy for international users—saving time and reducing maintenance effort.

Wide Range, Transparent Pricing

From entry-level to high-end models, our ultrasonic welders suit all needs and budgets. Clear classification and pricing let customers select the right configuration with confidence and no hidden costs.

Certified & Patent-Protected Tech

Our machines are CE, ISO-certified and backed by multiple patents. With strong R&D, we deliver safe, innovative, and performance-driven solutions for demanding industries worldwide.

Technical Data

| Category | Parameter Items |

|---|---|

| Technical Data | Machine Power: 300W/ 500W/800W/1000W/1200W/ 2000W/3000W/4000W/ 5000W/10000W |

| Pressure: 2000N/3000N/5000N | |

| Weight: 55KG/100KG | |

| Ultrasonic Controller | Operation Type: Desktop Type |

| Power Input: AC220V + 10% 50/60Hz | |

| Welding Stroke: 75mm/100mm, Customizable Stroke Available | |

| Dimension Specifications | Width×Depth×Height: 670mm × 400mm × 1165mm |

What Our Clients Say

Other welding processes

Customer FAQs

Does plastic welding really work?

Yes, plastic welding really works. When done correctly, it creates strong, durable bonds—often as strong as or stronger than the original plastic—especially with compatible thermoplastics.

What are the disadvantages of spin welding?

Spin welding can cause material deformation, limited to round parts, may produce flash, not suitable for brittle plastics, and requires precise alignment and rotational symmetry.

Is plastic welding expensive?

Plastic welding is usually affordable, but costs vary by method, equipment, and scale. Industrial setups cost more initially but save money in high-volume production.

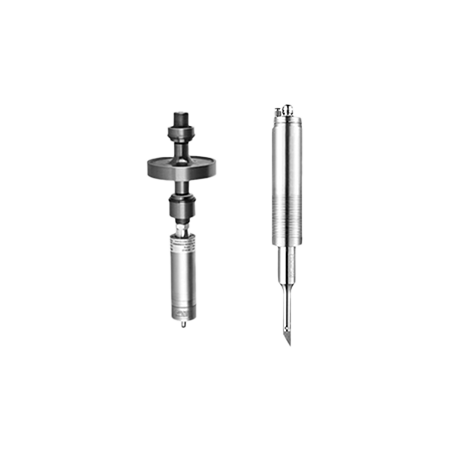

What is the process of spin welding plastic?

Spin welding joins thermoplastics by rotating one part against another under pressure, creating heat through friction to melt and fuse the surfaces.

How strong is plastic weld?

Plastic welds can be very strong, often matching or exceeding the base material’s strength when done properly with compatible plastics and correct technique.