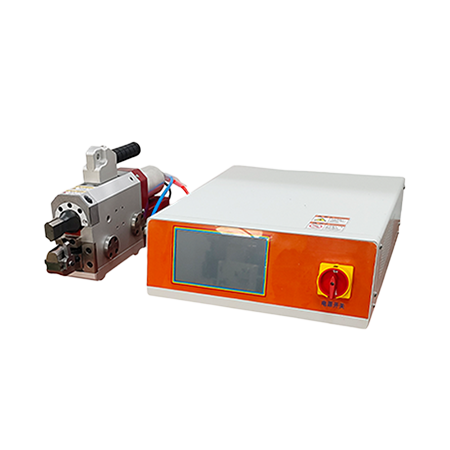

ultrasonic tube sealing machine

-

Integrated One-Step Process

Flame-free cutting and welding completed in a single operation. -Ensures stable, reliable quality and 30% improved production efficiency. -

Smart Quality Control

Automatic defect detection and alarm system for real-time monitoring. Human-machine interface guarantees consistent welding results. -

Energy Efficiency & Cost Savings

Reduces energy consumption by 40% and processing costs by 25%. Pollution-free operation compliant with eco-friendly standards. -

User-Friendly Design

Simple operation requiring minimal training.

Modular structure for low maintenance and easy servicing. -

Safety & Durability

Flame-free technology eliminates fire hazards.

Industrial-grade durability for continuous high-intensity workflows.

description

This metal tube sealing machine is equipped with an ultrasonic generator and an end-sealing device. It is commonly used for sealing copper or aluminum tubes. The machine is small in size, fast in sealing, and simple to operate. This ultrasonic metal tube sealing machine adopts high-frequency vibration pressing of ultrasonic waves, making it suitable for sealing thin-walled tubes. It features minimal thermal zone influence, high precision, and excellent sealing performance, making it suitable for mass production.

Ultrasonic metal tube sealing machines can stably seal copper tubes, aluminum tubes, etc. This sealing machine uses PLL technology, has the advantages of high-precision sealing, energy saving, high efficiency, and extended equipment life. It is widely used in applications such as refrigerant copper tube sealing, green plant fuel tube sealing, etc.

application

Refrigeration Industry

During the sealing of copper tubes, the Phase-Locked Loop (PLL) technology automatically adapts to varying tube diameters (e.g., φ6mm to φ25mm), ensuring leak-proof seals.

Automotive Manufacturing

For high-frequency sealing of aluminum fuel pipes, PLL enables stable performance under high-speed production line demands, maintaining precision and durability.

Medical Devices

In the sterile sealing of stainless steel catheters, PLL guarantees no Heat-Affected Zone (HAZ), preventing material oxidation and preserving biocompatibility.

Metal Tube Sealing Machine Video

Hyusonic’s ultrasonic tube sealer is designed specifically for copper and aluminum tube sealing in industries like HVAC, refrigeration, medical gas systems, and precision fluid control. It offers consistent, clean, and airtight welds without the need for brazing or flame, making it ideal for high-purity, leak-sensitive applications.

Technical data

| Parameter | Specifications | |

|---|---|---|

| Technical Data | Power | 2000W – 3000W |

| Frequency | 20kHz | |

| Working Air Pressure | 0.1 MPa – 0.7 MPa | |

| Input Voltage | 220V | |

| Key Features | High-power constant-power digital power supply and ultrasonic generator with mature PLL (Phase-Locked Loop) cycle technology (dual-in-one system). | |

| Welding Mode | Constant power welding mode with digitally adjustable power and weld time. | |

| Weight | 15 kg | |

| Dimensions | Length × Width × Height | 450 × 240 × 100 mm |

Customer FAQs

What is ultrasonic metal tube sealing machine?

The ultrasonic metal tube sealing machine can seal copper or aluminum tubes, effectively preventing the leakage of liquids or gases and ensuring the normal operation of pipeline systems. It also prevents external contaminants from entering the copper tubes, maintaining the purity of the fluids and protecting the tubes from corrosion and damage caused by external environments. This significantly prolongs the service life of the copper tubes.

How to weld multi-strand wires without fraying using ultrasonic splicers?

Use serrated anvils, apply 2000N–4000N clamping force, and set short weld times (0.1s–0.3s) to fuse strands uniformly.

How to validate weld strength in medical-grade wire harnesses?

Perform pull tests (≥80% base material strength), microsection analysis, and comply with ISO 13485 for hermetic seals.

How does ultrasonic wire harness welding improve conductivity compared to crimping?

Ultrasonic welding creates molecular bonds without oxidation, ensuring 99%+ conductivity. Crimping risks micro-gaps, leading to resistance buildup over time.

What is the maximum wire gauge an ultrasonic wire splicer can handle for automotive harnesses?

High-power machines (e.g., 4000W–6000W) reliably splice wires up to 10 AWG. For precision work (e.g., 24 AWG), use systems with 20kHz–40kHz frequency and 0.01mm displacement control.

Can ultrasonic wire splicers join copper and aluminum wires for hybrid harnesses?

Yes! Use 30kHz–35kHz frequency and pressure settings (e.g., 3000N) to fuse dissimilar metals without flux or solder.