ultrasonic lace machine

- Wireless & Needle-Free, High Welding Strength

- Single/Multiple Strips Simultaneous Cutting

- Smooth Edges, No Roughness

- Burr-Free Cutting, Customizable Patterns

description

Hyusonic ultrasonic lace machine utilizes high-frequency ultrasonic vibration to generate localized frictional heat at the material interface, inducing instantaneous thermoplastic melting and molecular bonding. This process eliminates traditional stitching or adhesives, ensuring seamless edges, hygienic seals, and superior tensile strength (up to 30MPa for nylon fabrics).

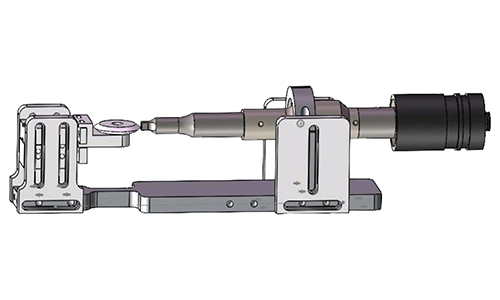

The ultrasonic lace sewing machine has Lateral drive and vertical drive structure designs to choose from. It is used to:

- Seaming: It can seam synthetic fiber fabrics without using needles and threads, achieving a water – tight effect.

- Welding: It melts and bonds fabric layers together through ultrasonic vibration, forming a firm connection.

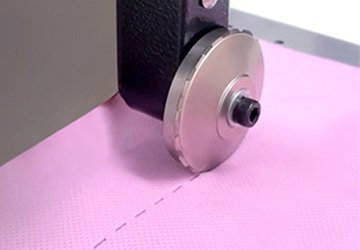

- Cutting: It cuts fabrics by precisely controlling the ultrasonic energy, leaving smooth edges without burrs.

- Embossing: By using embossing molds and ultrasonic vibration, it creates three – dimensional and delicate patterns on fabrics.

Technical data

| Parameter | Details | |

|---|---|---|

| Technical Data | Power | 1800W-2500W |

| System Frequency | 15kHz/18kHz/20kHz/28kHz /30kHz/35kHz/40kHz |

|

| Pressure | 2000N/3000N/5000N | |

| Weight | 55kg | |

| Generator | Welding Stroke | 10mm/20mm (Customizable) |

| Power Input | AC220V ±10%, 50/60Hz | |

| Weight | 55kg/100kg | |

| Dimensions | Length × Width × Height | 1200mm × 540mm × 1150mm |

Cases

The difference between different structures of ultrasonic lace sewing machines

Energy Transfer Direction Determines Processing Purpose:

Lateral Drive → Surface precision welding (decorative applications).

Vertical Drive → Deep-layer rapid welding (functional applications).

Mechanical Structure Design Adapts to Application Requirements:

Lateral systems are complex, ideal for customized production;

Vertical systems are simplified, optimized for standardized mass production.

Thermal Management Strategy Differences:

Thin materials require controlled heat input (lateral drive) to avoid over-melting;

Thick materials demand penetrating fusion (vertical drive) to ensure full-layer bonding.

Customer FAQs

What is ultrasonic lace sewing machine?

An ultrasonic lace machine is a highly efficient sewing and embossing device that utilizes ultrasonic technology.

What materials are suitable for ultrasonic lace machine?

The ultrasonic lace sewing machine is widely used in the clothing, home textile, toy, food, and medical industries. For example, it is used to process clothing lace, cuffs, collars, home textile products such as curtains and bed sheets, and non – woven products such as masks and surgical gowns.

Is it possible to customize the patterns and sizes of the lace sewn by the ultrasonic lace sewing machine?

Yes, ultrasonic lace sewing machines can usually be equipped with different flower wheels and molds to achieve different patterns and sizes. Moreover, some advanced machines support computer – aided design, which can customize various complex lace patterns according to customer requirements.

Can the ultrasonic lace sewing machine be used to process thick fabrics?

Yes, but the power and parameters need to be adjusted according to the thickness of the fabric. Generally, ultrasonic lace sewing machines have different power models to meet the processing requirements of fabrics with different thicknesses.

How does the ultrasonic lace sewing machine work?

It generates high – frequency oscillations through the ultrasonic generator, which are transmitted to the welding head. The welding head then transmits sound waves to the workpiece, causing friction between the molecules of the workpiece due to ultrasonic vibration. This friction generates heat, raising the temperature to the melting point of the material, thus achieving the effects of welding, cutting, and embossing.