Optional Configurations

- Servo-Driven Precision Control

- MES Integration (Industry 4.0 Ready)

- Automated Load/Unload Systems

- Vision-Based Inspection & Recognition

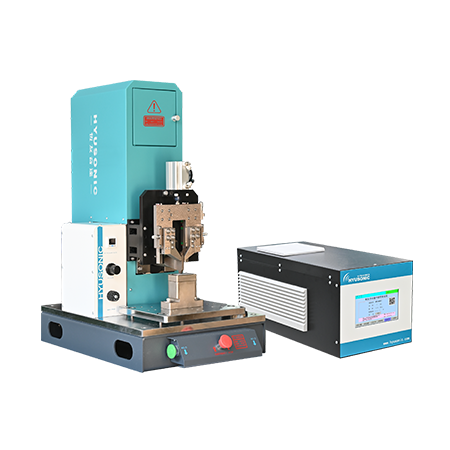

ultrasonic welder machine for battery tab welding m series

-

Full-Series Modular Design

Plug-and-Play Modularity: Rapid tooling swap (<10 mins) and scalable configurations for multi-product workflows. -

CE & ISO 9001 Certified

Compliant with EU Machinery Directive 2006/42/EC and global quality standards for risk-free global deployment. -

6 Welding Modes & 5 Trigger Modes

Programmable logic for complex applications (Time/Energy/Peak Power/Absolute Distance/Relative Distance/Ground Detect modes). -

Real-Time Monitoring & Quality Control

Dynamic data tracking (pressure/power/displacement) with automated fault alerts.

description

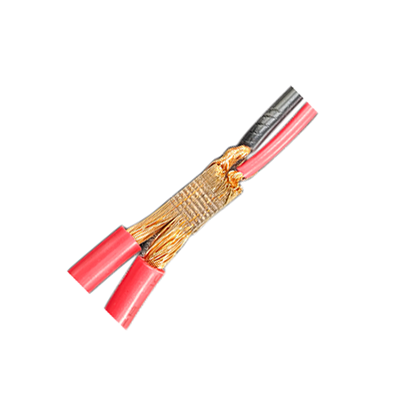

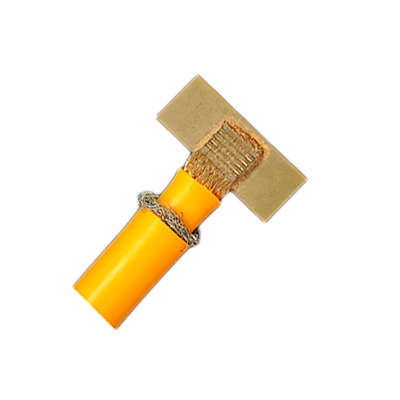

The M-series ultrasonic welding machine for metal welding uses a 100% German-imported system, offering stable quality comparable to international first-tier ultrasonic welding brands. It is mainly applicable for welding of non-ferrous metal wire harnesses, metal sheets, battery tabs, battery positive and negative poles, etc. Due to its low energy consumption, no need for consumables, fast welding speed, and the resistance value of welded products being nearly comparable to raw materials, ultrasonic metal welding machines have become perfect alternatives to traditional metal joining methods. The M-series ultrasonic metal welding machine supports Industry 4.0 upgrades, with multiple trigger dimensions for controlling welding precision, real-time monitoring, and welding protection. Therefore, it is perfectly suitable for industries requiring extremely high precision and stability, such as automotive batteries and power distribution.

Why M series Stands Out

100% German Ultrasonic System

We have in-depth technical cooperation with Germany and use 100% components of ultrasonic systems that meet international standards to ensure the stability and quality of the machines.

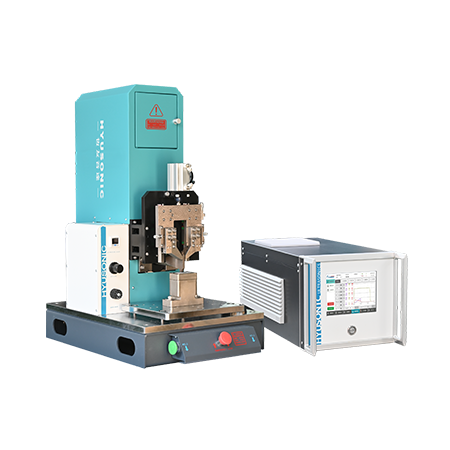

Latest Control Technology

The X series ultrasonic metal welding machines feature intelligent QC monitoring/alarm, Industry 4.0 integration, and multi-dimensional threshold control for 0.01mm precision, meet high-quality inspection standards.

Price & Service

HYUSONIC, a Chinese ultrasonic welding machine manufacturer, ensures first-tier quality via excellent supply chains at favorable prices, offering comprehensive trial welding, training, warranty and after-sales support.

Technical data

| Parameter | Specifications/Range | |

|---|---|---|

| Technical Data | Machine Power | 800W / 1200W / 2000W / 2500W / 3000W / 3600W / 4000W / 5000W / 6000W / 10000W |

| Frequency | 20kHz / 28kHz / 30kHz / 35kHz / 40kHz | |

| Power Input | AC220V ±10%, 50Hz/60Hz | |

| Pressure | 2000 – 5000N (customizable) | |

| Welding Stroke | 75mm / 100mm (customizable) | |

| Operation Type | Benchtop / Floor-integrated type | |

| Weight | 55KG / 160KG | |

| Welding (Range/Precision) | Energy Range | 1ws – 9999ws |

| Adjustable Displacement Precision | 0.01mm | |

| Welding Time | Range: 0.01s – 10s | |

| Dimensions | Frame (L×W×H) | 400mm × 680mm × 2010mm |

| Control Box (W×D×H) | 265mm × 580mm × 255mm |

welding cases

Customer FAQs

What factors determine the optimal power selection for an ultrasonic metal welding machine?

Hyusonic M series ultrasonic metal welding machine uses 100% German imported system. The welding stability and quality are almost identical to those of international first-line brands (Telsonic, Branson, Harrmann, etc.). However, thanks to the perfect supply chain and cost advantages, Hyusonic’s ultrasonic metal welding machine has a better price advantage.The power (800W to 10000W) depends on material thickness, joint design, and production speed. Higher power suits thicker metals like aluminum, while lower power works for thin foils. If you need ultrasonic welding equipment, choose Hyusonic to request a quote.

What are the cost benefits of switching from laser welding to ultrasonic metal welding?

Ultrasonic welding reduces energy costs (no consumables), eliminates shielding gas, and operates at lower voltages (AC220V), saving 30-50% in long-term expenses.

Why is my ultrasonic metal welder producing inconsistent weld joints?

Check for misaligned tooling, uneven pressure, or frequency drift. Calibrate welding time (0.01s-10s range) and verify energy output (1ws-9999ws).

How does system frequency (20kHz vs. 40kHz) affect weld strength in ultrasonic machines?

Lower frequencies (20kHz-30kHz) provide deeper penetration for thick metals, while 40kHz offers precision for thin, delicate components.

What safety standards should be followed when operating high-power (10,000W) ultrasonic welders?

Use PPE, secure grounding (AC380V input), ensure proper machine weight (160KG stability), and install vibration-dampening mounts.