Ultrasonic Welding Nonwoven Fabrics

The ultrasonic welding of non-woven fabrics relies on their thermoplastic polymer material properties and unique physical structure, where frictional heat generated by high-frequency vibration melts and bonds the fiber interfaces. Thermoplastic polymer materials such as PP and PET are selected, whose molecular chains exhibit segmental mobility and diffusion capability at high temperatures, with melting points matching the instantaneous heat generation range of ultrasonic welding. The type and content of additives should balance heat resistance and welding adaptability. The fibers form a three-dimensional interwoven non-woven network, where density and thickness determine energy penetration efficiency. Thicker fibers and a compact structure optimize heat conduction and uniform distribution. For multi-layer composite structures, compatibility of melting points among layers must be ensured to avoid welding failure due to thermal conductivity differences. This collaborative design of material properties and physical structure enables ultrasonic energy to act precisely on the welding interface, achieving efficient and environmentally friendly fusion bonding.

Applications of Ultrasonic Welding Nonwoven Fabrics

Leveraging Hyusonic’s ultrasonic systems (welding machines, lacing machines, seaming equipment, and cutters), these applications span medical, industrial, and consumer sectors, integrating welding, cutting, and edge sealing with technical efficiency:

Ultrasonic Welding of Non-Wovens

- Medical & Hygiene Products

- Mask manufacturing: Spot-welding ear loops and nose bridges on N95/KN95 masks via iQ-series welders (0.2s fast welding), with lace machines forming waterproof edge seals.

Surgical gown seams: Seam welding replaces stitching for sterile, airtight bonds.

- Mask manufacturing: Spot-welding ear loops and nose bridges on N95/KN95 masks via iQ-series welders (0.2s fast welding), with lace machines forming waterproof edge seals.

- Industrial & Automotive

- Filtration materials: High-frequency welding of multi-layer PET/PP non-wovens for car air/oil filters, ensuring heat resistance (150°C long-term use).

- Noise insulation: Composite welding of non-woven acoustic felts to metal/plastic parts using X-series auto frequency tracking.

- Packaging & Daily Use

- Shopping bags: Base and side sealing of PP non-woven bags via ST-series roll welding (10–20m/min speed), eliminating glue.

- Wet wipe packaging: Hermetic sealing with energy-mode control (Time/Energy/Peak Power) for leak-proof integrity.

2. Ultrasonic Cutting of Non-Wovens

- Medical & Protection

- Mask/surgical gown cutting: High-precision cuts via handheld/automated systems, producing burr-free edges to prevent fiber shedding in cleanrooms.

- Medical dressings: Customized shape cutting of sterile nonwovens, dynamic power regulation

- Industrial & Composites

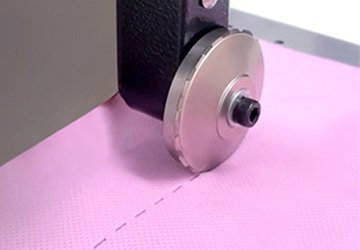

- Air filter forming: Radial rolling cutters for ring-shaped filter meshes (0.01mm precision), ideal for HEPA filters.

- Lithium battery separators: Low-heat cutting preserves insulation properties, suitable for electronic-grade environments.

- Consumer & Food Packaging

- Home textiles: Curtain linings cut and edge-sealed simultaneously by lacing machines (Vertical Drive), with customizable decorative patterns.

- Food packaging: Freeze-resistant cutting of non-woven pouches, preventing material adhesion via non-contact ultrasonic vibration.

3. Edge Sealing & Decorative Lacing

- Medical & Hygiene Edge Sealing

- Medical & Hygiene Edge Sealing

Mask edging: Lace machines with embossed wheels create sealed, decorative corrugations for aesthetic and functional integrity.

Diaper edges: Water-tight welding of non-woven layers (2000–5000N pressure control) to prevent leakage.

- Medical & Hygiene Edge Sealing

- Apparel & Home Decor

- Activewear linings: Embossed edge sealing with 3D patterns via computer-aided lace machine molds.

- Curtain trims: Waterproof edge finishing combined with laser-cut designs, replacing traditional stitching.

- Industrial & Agricultural

- Composite packaging: Sealing non-woven-PE film laminates for cosmetics/foods, ensuring multi-layer bond strength.

- Agricultural mulch: Edge sealing to prevent wind tearing, integrated into production lines via modular cutter systems.

Advantages of Ultrasonic Welding Non-woven Fabric Technical

- Stable welding consistency: HYUSONIC ultrasonic welding for nonwovens ensures the distance between materials and tools remains constant throughout the welding process, unaffected by tool thermal expansion. This guarantees the stability and repeatability of welding quality, enabling high-quality continuous processing irrespective of production speed.

- Fast and efficient: Ultrasonic welding of nonwoven features high-speed stability without preheating, enabling material melting and bonding within milliseconds. It also integrates embossing, lamination, and cutting simultaneously, significantly enhancing production efficiency.

- Versatile Application Scenarios: Applied across industries—including film welding for coffee capsules/beverage packaging (packaging sector) and production of surgical masks/diapers/feminine care products (nonwoven field)—it satisfies diverse nonwoven film welding needs.

contact us for ultrasonic welding solutions

Fill up the Form and Ask Your Queries

Address

No. 168 Weita Road, Zhangpu Town , Kunshan , Suzhou , Jiangsu , China

Phone/WhatsApp

+(86) 13776317970

rui.zhang@hyusonic.com

hyusonic2009@gmail.com

Why HYUSONIC is Trusted by 5000+ Clients

- Professional Technical Support : 20 years of ultrasonic welding expertise guarantees 100% feasibility assessment for your product's welding needs.

- Thousands of Welding Experiences : With experience serving 5,000+ global clients and welding expertise across 1,000+ product types, we deliver accurate, complete welding solutions for your specific needs.

- German Technology : Hyusonic originated as a German OEM and has established deep technical cooperation with Germany's leading ultrasonic welding experts. We hold ISO 9001, CE certifications, and multiple patents, ensuring premium quality and innovation.