How to Choose the Right Welding Equipment: A Comprehensive Guide

When it comes to manufacturing and assembly processes, selecting the appropriate welding equipment is crucial for ensuring high-quality results, efficiency, and cost-effectiveness. With a variety of welding techniques available, including ultrasonic welding, hot melt welding, hot plate welding, and laser welding, it can be challenging to determine which one is best suited for your specific needs. In this article, we will explore the key factors to consider when choosing welding equipment and compare the different traditional welding processes to help you make an informed decision.

How do I know which welder to buy?

The first step in choosing the right welder is to understand your specific application requirements. Consider the following factors:

- Material Type and Thickness: Different welding processes are suitable for different materials and thicknesses. For example, ultrasonic welding is ideal for joining thermoplastics, while laser welding is commonly used for metals and thin materials.

- Weld Strength and Quality: Determine the required weld strength and quality for your application. Some welding processes, such as ultrasonic welding, laser welding, can achieve high-strength, precision welds, while others may be more suitable for lower-strength applications.

- Production Volume: If you are working on high-volume production, you will need a welding process that can handle the demand efficiently. Automated welding systems, such as ultrasonic welding machines, can significantly increase productivity.

- Cost and Budget: Consider your budget and the overall cost of the welding equipment, including purchase price, maintenance, and operating costs. Cheaper welders may have limited features and capabilities, while more expensive models may offer advanced features and higher performance.

- Operator Skill Level: Some welding processes, such as laser welding, require highly skilled operators, while others, such as ultrasonic welding, are relatively easy to operate and require minimal training.

What is the difference between cheap and expensive welders?

The price of a welder can vary significantly depending on its features, capabilities, and brand. Here are some key differences between cheap and expensive welders:

- Build Quality and Durability: Expensive welders are typically built with higher-quality materials and components, making them more durable and reliable. Cheaper welders may be made with lower-quality materials and may not last as long.

- Performance and Precision: More expensive welders often offer higher performance and precision, allowing for more accurate and consistent welds. They may also have advanced features, such as adjustable welding parameters and automatic control systems.

- Safety Features: Expensive welders usually come with more comprehensive safety features, such as automatic shut-off systems, overheat protection, and arc shielding. These features help to protect operators from potential hazards.

- Warranty and Support: Higher-priced welders often come with longer warranties and better customer support. This can provide peace of mind and ensure that you have access to assistance if you encounter any issues with your equipment.

Comparison of Different Welding Processes

Ultrasonic Welding

Advantages

- Broad Compatibility: Works with various thermoplastics and can join plastics to other materials.

- High-Quality Welds: Produces clean, strong, and hermetic seams.

- Fast & Automated: Quick welding (ms – s) and ideal for high-volume production.

- Cost & Eco-Friendly: Low equipment and operating costs; no consumables.

- Easy to Use: Minimal training required for operation.

Disadvantages

- Material Specific: Mainly for thermoplastics.

- Thickness Limit: Unsuitable for thick materials.

Hot Melt Welding

Advantages

- Good Compatibility: Suits many thermoplastics and mixed-material joining.

- Strong Welds: Achieves durable, chemically resistant joints.

Disadvantages

- Slow Process: Long welding times, not for mass production.

- High Costs: Expensive equipment, high energy use, and consumables add expense.

- Skilled Operators: Needs trained staff; regular equipment maintenance.

- Environmental Impact: Consumables harm the environment.

Hot Plate Welding

Advantages

- Wide Application: For various thermoplastics and large/complex parts.

- Quality Welds: Delivers strong, dimensionally accurate joints.

Disadvantages

- Low Efficiency: Slow welding, fits batch production.

- Costly: Expensive gear, high energy consumption, and extra costs from consumables.

- Complex Operation: Requires skilled operators and regular calibration.

- Eco-Unfriendly: Consumables pollute the environment.

Laser Welding

Advantages

- Versatile Material Use: Works on metals, alloys, and some non-metals; joins different materials and thicknesses.

- Precise Welds: Creates narrow, deep, and high-integrity seams.

- Rapid Production: Short welding times; great for mass production.

Disadvantages

- High Costs: Expensive equipment and high operating expenses.

- Skilled Labor: Demands trained professionals; complex equipment upkeep.

- Strict Safety: Needs specialized safety gear for operation.

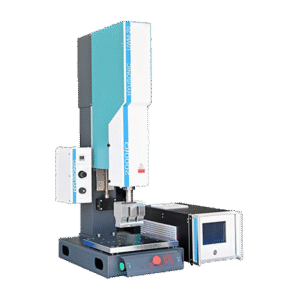

Why Choose Hyusonic Welding Equipment?

At Hyusonic, our high-quality welding solutions center on ultrasonic machines, supported by hot plate and hot melt models. Serving medical, electronics, automotive, food, and consumer goods sectors, we can handle diverse products, such as automotive plastic components and metal wire harnesses, FDA-compliant medical devices, cosmetic tube sealing, non-woven fabric cutting, food slicing, and food packaging welding. .

Quality & Tech: Built with proprietary smart tech and German ultrasonic components, our machines ensure consistent, reliable welds.

Custom Fit: Our 20+ year experienced engineers tailor solutions to your unique needs, from design to testing.

Cost Efficiency: Energy-saving, easy-maintain equipment cuts costs while boosting productivity—no compromise on quality.

Support: Our experts are always ready to answer questions, offer technical help, and provide training and maintenance.