How to Cut Carbon Fiber: Best Methods & Tools Explained

Publish Data:2025.7.17 Author: Hyusonic

Cutting carbon fiber can be a tricky process if you don’t use the right tools or techniques. Whether you’re working with carbon fiber sheets, tubes, or rods, it’s essential to choose the best way to cut carbon fiber to ensure precision and avoid damaging the material. In this guide, we’ll cover how to cut carbon fiber, the best tools for the job, and a comparison of the most popular cutting methods, including water jet cutting, laser cutting, ultrasonic cutting, and circular saw cutting.

Why Cutting Carbon Fiber Requires Special Care

Carbon fiber is known for its strength-to-weight ratio and its durability. However, its unique composition — a combination of carbon filaments and resin — makes it prone to damage if not cut properly. Cutting carbon fiber improperly can result in:

Delamination: where the fibers separate from the resin matrix.

Rough Edges: causing issues for subsequent assembly or finishing.

Thermal Damage: which can affect the integrity of the material.

To avoid these issues, it’s crucial to understand the best tools and techniques for cutting carbon fiber.

How Do You Cut Carbon Fiber?

When cutting carbon fiber, the key is to use the right cutting method for the material’s thickness and your project requirements. Let’s explore the most effective ways to cut carbon fiber:

1. Water Jet Cutting Carbon Fiber

Overview:

Water jet cutting is one of the most popular methods for cutting carbon fiber, especially when you need to avoid heat and keep the material intact. This method uses high-pressure water, sometimes mixed with abrasives, to slice through the carbon fiber sheets.

Advantages:

No Heat Damage: Since there is no heat involved, water jet cutting ensures that the carbon fiber’s structural integrity is maintained, making it ideal for high-performance applications.

Clean Edges: It produces smooth, clean cuts without any fraying or delamination.

Versatile: Water jet cutting can handle both thin and thick carbon fiber materials.

Disadvantages:

Slow: Water jet cutting can be slower compared to other methods like laser or circular saw cutting.

Costly: The equipment can be expensive, and maintenance is required to keep the jet nozzles in good condition.

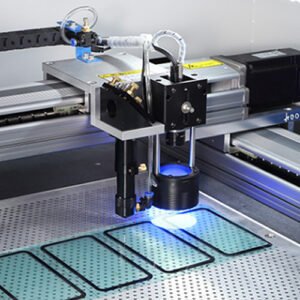

2. Laser Cutting Carbon Fiber

Overview:

Laser cutting is a highly accurate cutting method that uses focused laser beams to melt or vaporize the material. It’s an ideal method for cutting intricate patterns or designs into carbon fiber.

Advantages:

Precision: Laser cutting allows for high-precision cuts with very little post-processing required.

Speed: It’s a relatively fast cutting method, especially for thinner materials.

No Physical Contact: Since the laser doesn’t touch the material, it minimizes the risk of damaging the carbon fiber during the process.

Disadvantages:

Heat Affected Zones: Laser cutting generates heat, which can damage the resin and cause microcracks in the carbon fiber. This is a concern for high-performance parts that require structural integrity.

Thickness Limitations: Laser cutting works best for thinner carbon fiber sheets. For thicker materials, the laser may not penetrate effectively.

3. Ultrasonic Cutting Carbon Fiber

Overview:

Ultrasonic cutting uses high-frequency sound waves to create vibrations that cut through the carbon fiber material. This method is known for its precision and minimal heat generation.

Advantages:

Low Heat Generation: Since ultrasonic cutting doesn’t involve heat, it avoids the thermal damage often seen with other methods like laser cutting.

Precision: Ultrasonic cutting is excellent for precise, fine cuts and can be used for both thin and moderately thick carbon fiber sheets.

Minimal Fraying: It produces clean cuts with minimal fraying, which is critical when working with high-quality carbon fiber.

Disadvantages:

Limited Thickness: While it’s great for thinner materials, ultrasonic cutting might not be the best choice for very thick carbon fiber, as the vibrations may not penetrate deep enough.

Specialized Equipment: Ultrasonic cutting systems require specific machinery that can be a significant investment upfront.

4. Circular Saw Cutting Carbon Fiber

Overview:

Circular saws are a common tool used for cutting carbon fiber, particularly for larger, thicker sheets or when speed is a priority. Using a circular saw with a diamond blade is one of the most straightforward ways to cut carbon fiber.

Advantages:

Fast: Circular saws are one of the quickest ways to cut through carbon fiber, especially for thicker sheets.

Cost-Effective: Compared to water jet or laser cutting, circular saws are less expensive and widely available.

Versatile: Circular saws can handle larger cuts and are great for general-purpose applications.

Disadvantages:

Heat Generation: Circular saws can generate heat, which can result in damage to the resin in carbon fiber, leading to delamination and rough edges.

Messy: Cutting carbon fiber with a circular saw can produce a lot of dust, which is harmful to both your health and the material.

Best Way to Cut Carbon Fiber

So, what’s the best way to cut carbon fiber? The best method really depends on your needs:

For high precision with no thermal damage: Ultrasonic cutting offers the perfect balance of precision and low heat, making it the ideal choice for cutting carbon fiber when quality is paramount.

For intricate designs and fast cutting: Laser cutting is ideal, but keep in mind the potential for thermal damage, especially if you are working with thicker sheets.

For fast and cost-effective cutting: Circular saws are great for thicker materials and larger projects, but be mindful of heat generation.

For larger, industrial-scale cuts: Water jet cutting is the best for avoiding thermal damage while ensuring a clean, smooth cut, but it comes at a higher cost and slower pace.

Carbon Fiber Cut Tools: What You Need to Know

If you’re wondering how to cut carbon fiber sheets or how to cut carbon fiber sheets with precision, understanding the right carbon fiber cut tools for the job is essential. From specialized saws to ultrasonic systems, each tool has its place, and investing in the right one can save time and money.

If you’re working on high-performance applications and need the most reliable, precise, and clean cuts, consider an ultrasonic cutting system. It’s ideal for industries that demand high-quality, heat-free cuts without compromising the structural integrity of the material.

Conclusion

Choosing the right cutting method for carbon fiber can be the difference between a successful project and one full of complications. Whether you’re using laser cut carbon fiber, water jet cutting, ultrasonic cutting, or circular saw cutting, each method has its own set of advantages and drawbacks. By understanding these options, you can select the best way to cut carbon fiber for your needs.

For those looking to maximize precision and minimize heat damage, an ultrasonic cutting system is a smart investment. It’s the optimal solution for high-end applications where carbon fiber’s integrity is paramount.