Industry Ultrasonic Cutting

Ultrasonic cutting: Achieves material separation via 20-40kHz high-frequency vibration, generating frictional heat (up to melting/softening point) to reduce material strength. E.g., plastic cutting weakens intermolecular forces through vibration, enabling “shearing” after softening.

Mechanical energy tearing: For brittle materials, vibration-induced mechanical stress exceeds tensile strength, triggering micro-crack propagation and fracture.

What materials are suitable for ultrasonic cutting?

Flexible Materials

Carbon fiber composites, glass fiber boards, and PCB boards (laminated materials).

Key Advantage: Ultrasonic vibration synchronously cuts phases with varying hardness, preventing delamination and fiber fraying (ideal for materials like carbon fiber boards).

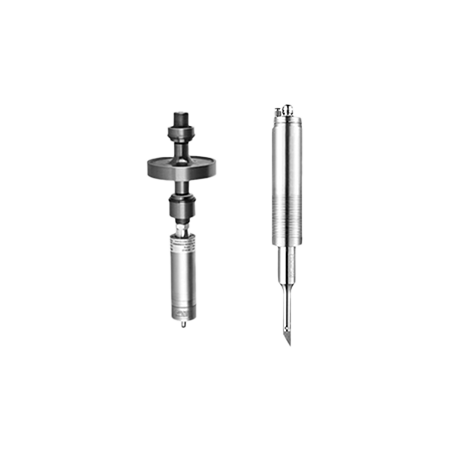

Hyusonic Ultrasonic Cutting Machine

Hyusonic ultrasonic cutting equipment adopts a modular design. We can produce portable handheld cutting systems, automatic cutting equipment (horizontal and vertical drive), ultrasonic lacing machines, and ultrasonic seam machines.

contact us for ultrasonic welding solutions

Fill up the Form and Ask Your Queries

Address

No. 168 Weita Road, Zhangpu Town , Kunshan , Suzhou , Jiangsu , China

Phone/WhatsApp

+(86) 13776317970

rui.zhang@hyusonic.com

hyusonic2009@gmail.com

Why HYUSONIC is Trusted by 5000+ Clients

- Professional Technical Support : 20 years of ultrasonic welding expertise guarantees 100% feasibility assessment for your product's welding needs.

- Thousands of Welding Experiences : With experience serving 5,000+ global clients and welding expertise across 1,000+ product types, we deliver accurate, complete welding solutions for your specific needs.

- German Technology : Hyusonic originated as a German OEM and has established deep technical cooperation with Germany's leading ultrasonic welding experts. We hold ISO 9001, CE certifications, and multiple patents, ensuring premium quality and innovation.