Laser Welding vs Ultrasonic Welding: A Comprehensive Comparison for Modern Manufacturing

Introduction

In today’s rapidly evolving manufacturing landscape, the need for precise, reliable, and efficient joining methods has never been greater. Two technologies that have garnered significant attention are laser welding and ultrasonic welding. While both offer clean, automated, and high-performance welding solutions, they operate on fundamentally different principles and are suited for distinct applications.

This in-depth guide provides a technical and practical comparison between these two joining methods, covering everything from operating principles and material compatibility to cost, efficiency, and industry applications. Whether you’re working with thermoplastics, non-ferrous metals, or complex assemblies, understanding the strengths and limitations of each process is crucial for optimizing your manufacturing outcomes.

1. Understanding the Principles

1.1 What Is Laser Welding?

Laser welding is a fusion welding technique that utilizes a high-powered laser beam to melt and join materials at their interface. The energy is precisely focused, allowing for deep penetration and narrow weld zones. It’s commonly used in the aerospace, automotive, electronics, and medical device industries due to its high precision and strength.

Key Features:

High energy density

Deep weld penetration

Non-contact process

Requires optical access to joint

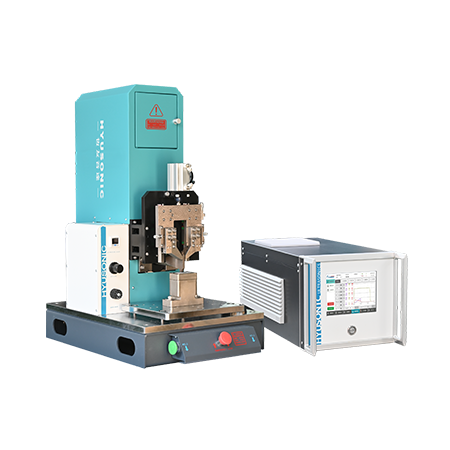

1.2 What Is Ultrasonic Welding?

Key Features:

No need for filler or adhesives

Low thermal impact

Extremely fast welding time

Ideal for thin plastics and foils

2. Materials and Compatibility

2.1 Materials Suitable for Laser Welding

Laser welding is highly effective for:

Stainless steel

Titanium

Aluminum

Nickel alloys

Certain plastics (if at least one layer absorbs the laser)

Due to its high thermal input and deep penetration, it’s ideal for thicker materials, precision welds, and hard-to-reach spots.

2.2 Materials Suitable for Ultrasonic Welding

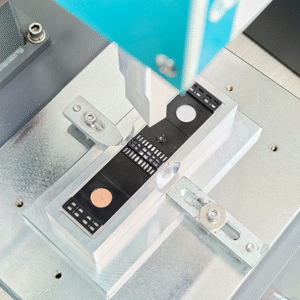

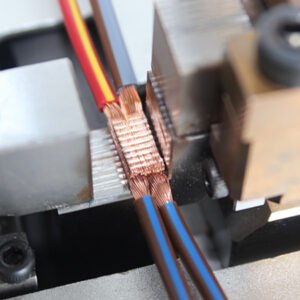

Ultrasonic welding is best for:

Thermoplastics (e.g., ABS, PP, PC)

Thin non-ferrous metals (copper, aluminum, brass)

Multilayer film packaging

Delicate electronics

Its low heat profile makes it particularly useful in environments where material degradation is a concern, such as in medical packaging or battery tab welding.

3. Joint Design and Weld Strength

3.1 Joint Types and Geometries

Laser welding supports a variety of joint configurations:

Butt joints

Lap joints

Fillet joints

Edge welding

Ultrasonic welding typically requires custom joint designs, such as:

Energy directors (in plastics)

Overlapping surfaces

Interference fit features

3.2 Strength and Durability

Laser welds offer exceptional mechanical strength, particularly for metals, and are resistant to corrosion and fatigue.

Ultrasonic welds, while not as deep or strong in metals, can be extremely durable in plastics and are highly repeatable for mass production.

4. Speed, Efficiency, and Automation

4.1 Welding Speed

Ultrasonic welding: welding time as fast as 0.1–1 second per cycle

Laser welding: varies based on material and thickness but generally fast

Ultrasonic systems often outperform laser systems in cycle speed for thin plastic applications.

4.2 Automation Capabilities

Both methods are compatible with Industry 4.0 and can be:

Integrated into robotic arms

Programmed for high-volume production

Monitored via real-time sensors

However, ultrasonic welding machines are generally easier to maintain and operate at a lower cost, making them favorable for low to mid-volume manufacturers.

5. Heat Impact and Thermal Distortion

One of the most critical distinctions between the two technologies lies in their thermal profiles.

5.1 Laser Welding Thermal Impact

Laser welding creates a heat-affected zone (HAZ) that can:

Alter microstructure

Introduce internal stresses

Lead to distortion in thin materials

Proper thermal management and clamping are essential to minimize defects.

5.2 Ultrasonic Welding Thermal Profile

Ultrasonic welding is a low-heat process, making it ideal for:

Temperature-sensitive materials

Electronics

Precision assemblies

This also reduces energy consumption and eliminates cooling time, boosting overall efficiency.

6. Cost Comparison

6.1 Equipment Cost

| Cost Factor | Ultrasonic Welding | Laser Welding |

|---|---|---|

| Initial Investment | $10,000–$50,000 | $50,000–$300,000+ |

| Maintenance | Low | Moderate to High |

| Operator Training | Minimal | Advanced |

| ROI | Faster in high-volume runs | Depends on use case |

Ultrasonic systems are often more cost-effective, especially for plastic and small metal part manufacturers.

7. Safety and Environmental Factors

7.1 Safety Considerations

Laser systems require:

Enclosed workstations

Protective eyewear

Fume extraction systems

Ultrasonic systems are:

Generally safer to operate

Do not emit light radiation

Quieter (with proper sound shielding)

7.2 Environmental Impact

Ultrasonic welding is considered more environmentally friendly due to:

Lower energy use

No need for consumables

Less waste generation

8. Defect Types and Quality Control

8.1 Common Laser Welding Defects

Porosity

Cracking

Spatter

Incomplete penetration

8.2 Common Ultrasonic Welding Defects

Incomplete fusion

Misalignment

Weak weld due to surface contamination

Quality control in both processes can be enhanced with:

Real-time monitoring

Non-destructive testing (NDT)

Smart sensors

9. Industrial Applications

9.1 Laser Welding Applications

Automotive body-in-white assembly

Aerospace turbine components

Electronic enclosures

Medical implant sealing

9.2 Ultrasonic Welding Applications

EV battery tab welding

Food packaging sealing

Disposable medical device assembly

Consumer electronics housing

Each technology has clear domains where it dominates, and choosing the right one can improve product quality, speed, and regulatory compliance.

10. Choosing the Right Technology

When deciding between laser and ultrasonic welding, consider:

| Factor | Best Choice |

|---|---|

| Thin thermoplastics | Ultrasonic welding |

| Thick metals | Laser welding |

| Cost-sensitive projects | Ultrasonic welding |

| Deep penetration welds | Laser welding |

| Non-contact requirements | Laser welding |

| Fast mass production | Ultrasonic welding |

| Visual aesthetics | Laser welding |

Conclusion

Both laser welding and ultrasonic welding represent cutting-edge solutions in modern manufacturing. While laser welding offers unmatched strength, precision, and flexibility for metals and complex geometries, ultrasonic welding delivers speed, economy, and thermal efficiency for plastics and delicate assemblies.

The key is not choosing the “better” technology but selecting the right tool for the right job. Manufacturers must evaluate their material types, throughput requirements, budget constraints, and product specifications before making an investment.

With continuous advancements in automation, sensor integration, and material science, both technologies are set to evolve further—enabling smarter, faster, and more sustainable manufacturing processes.