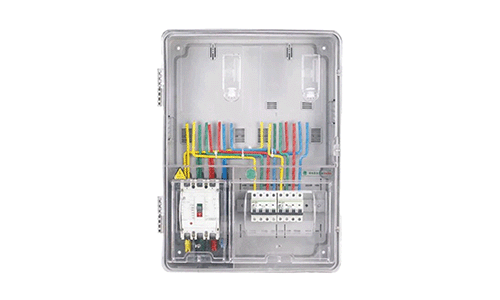

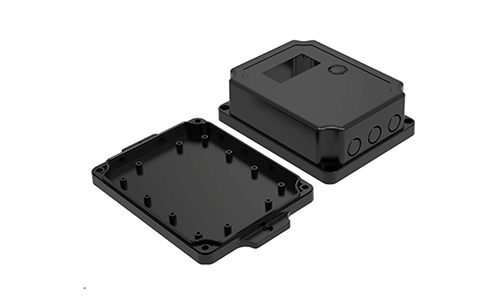

electronics

Ultrasonic plastic welding is the preferred method for bonding charger cases, IoT device housings, and consumer electronics enclosures, delivering strong, clean, and repeatable seals without adhesives or screws.

- Airtight & Dustproof Seals – Ideal for waterproof/weatherproof electronics (IP67+)

- No Thermal Damage – Low-heat process protects sensitive PCB components

- 3-5x Faster Than Glue/Screws – Typical cycle time: 0.2~1 second

- Material Savings – Up to 30% thinner walls vs. mechanical fasteners

Ultrasonic welding is ideally suited for the welding requirements of the electronics industry. Electronic devices typically demand high-precision welding while ensuring strict airtight and watertight seals to extend service life. Ultrasonic welding offers advantages of high precision and excellent sealing performance. Compared with traditional processes such as adhesive bonding and hot-melt welding, ultrasonic welding of electronic device housings eliminates adhesive overflow, reducing the risk of damage to internal electronic components. This significantly improves welding yield rates and enhances production efficiency.

contact us for ultrasonic welding solutions

Address

No. 168 Weita Road, Zhangpu Town , Kunshan , Suzhou , Jiangsu , China

Phone/WhatsApp

+(86) 13776317970

rui.zhang@hyusonic.com

hyusonic2009@gmail.com

Why HYUSONIC is Trusted by 5000+ Clients

- Professional Technical Support : 20 years of ultrasonic welding expertise guarantees 100% feasibility assessment for your product's welding needs.

- Thousands of Welding Experiences : With experience serving 5,000+ global clients and welding expertise across 1,000+ product types, we deliver accurate, complete welding solutions for your specific needs.

- German Technology : Hyusonic originated as a German OEM and has established deep technical cooperation with Germany's leading ultrasonic welding experts. We hold ISO 9001, CE certifications, and multiple patents, ensuring premium quality and innovation.