Desktop Heat Staking Machine

-

Precision Temperature Control

Programmable heating zones for accurate staking -

Compact Desktop Design

Space-saving structure ideal for workbenches and labs -

CE & ISO 9001 Certified

Compliant with EU safety standards and international quality management. -

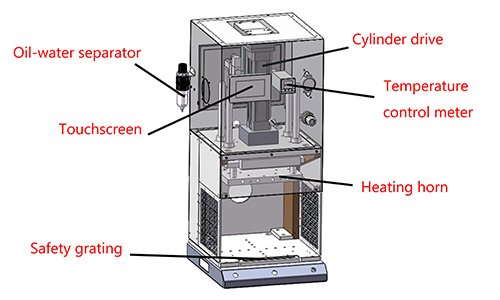

User-Friendly Interface

Intuitive touchscreen or button operation -

Multi-Material Compatibility

Works with ABS, PP, PC, glass-filled plastics, etc.

description

The Desktop Heat Staking Machine is a compact yet powerful solution for precision thermal staking of thermoplastic components. Designed for engineering labs, small-scale production, and high-mix environments, this benchtop system combines high temperature accuracy with modular flexibility. It uses a heated metal probe to soften and deform plastic bosses, rivets, or studs, permanently locking them to mating components without screws or adhesives.

With a customizable staking horn, programmable temperature, and dwell time, as well as optional digital displays, operators can easily adapt to a wide variety of plastic types, including ABS, PP, PC, PA, and glass-fiber-reinforced materials. The machine supports multi-point staking, height-adjustable fixtures, and consistent repeatability for reliable performance across batches. Its clean, semi-automated operation makes it ideal for applications in automotive electronics, medical devices, and consumer product assemblies.

Whether you’re developing prototypes or refining assembly processes, the Desktop Heat Staking Machine delivers industrial-grade results in a space-efficient, operator-friendly format.

Why Desktop Heat Staking Machine Stand Out

Precision Thermal Control

The machine offers highly accurate temperature regulation and programmable dwell time, ensuring consistent results across different plastic types, including glass-fiber-reinforced materials.

Compact & Modular Design

With a small footprint and modular head system, it’s perfect for benchtop environments and adaptable to both single-point and multi-point staking operations.

Tool-Free Setup & Repeatability

Quick-change fixtures and intuitive controls allow fast setup and repeatable performance—ideal for prototyping, low-volume production, and high-mix assembly lines.

Advantages

Beyond core features, this desktop heat staking machine stands out for its low maintenance needs, energy efficiency, and compatibility with automation-ready systems. Its quiet operation and ergonomic layout also improve operator comfort, making it ideal for extended use in precision-driven environments like medical, automotive, and electronics assembly.

What Our Clients Say

Customer FAQs

What is a heat staking machine used for?

A heat staking machine is used to permanently join thermoplastic components by melting and reforming plastic studs or bosses over another part, creating a strong mechanical bond without adhesives or fasteners.

How does a heat staking machine work?

The machine uses a heated tool (called a stake) to soften a plastic projection, which is then formed into a specific shape to hold parts together. It combines heat, pressure, and dwell time for precise joining.

What materials are compatible with heat staking?

Heat staking works best with thermoplastics such as ABS, PP, PC, PA, and their glass-filled variants. It can also join plastic to non-plastic components like PCBs, metals, or films.

What industries use heat staking machines?

Heat staking is widely used in automotive, consumer electronics, medical devices, appliances, and plastic enclosures that require clean, permanent fastening.

How do I choose the right heat staking machine?

Consider part size, production volume, compatible materials, heating method (thermal, infrared, etc.), and whether desktop or inline automation suits your application best.