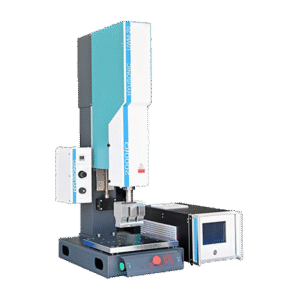

handheld Heat Staker

- Portable Operation

- Safe insulation

- Multi-scene riveting

- Replaceable horn

Description

This handheld heat staking machine allows for manual control of pressure and start/stop, providing flexibility. The welding horn is thermally treated to ensure safety and reduce the heat-affected zone. It is designed for staking metal and plastic components, as well as plastic-to-plastic staking, capable of welding angles that are difficult for large heat staking machines to reach, all at a highly cost-effective price.

Advantages

Safe and Versatile

The Hyusonic handheld heat staking machine offers flexible operation and can be used for direct riveting between metal and plastic, as well as between plastic and plastic. It features high precision, minimal heat-affected zones, and a high cost-performance ratio.

Various Shapes of Horn

This handheld heat staking machine can replace horns of different shapes to meet the welding needs of other scenarios. The welding horn is easy to replace and has a heat-insulating shell.

What Our Clients Say

Customer FAQs

How much does an industrial plastic ultrasonic welder cost?

The price of ultrasonic welding machine depends on the component structure of ultrasonic system, welding requirements and precision to be achieved. The general price ranges from several thousand to hundreds of thousands. If you need ultrasonic welding equipment, choose hyusonic to request a quote.

How fast is ultrasonic plastic welding vs hot plate welding?

Ultrasonic welding is 3-5x faster (typical cycle time 0.2-2s vs 10-30s).

How to choose between 20kHz and 40kHz for plastic welding?

20kHz: Better for thick parts (5-10mm) like automotive bumpers

40kHz: Ideal for thin/delicate plastics (0.5-3mm) like medical devices

Can ultrasonic welders join dissimilar plastics?

Yes, but only compatible pairs (e.g., ABS to PC). Use our Material Compatibility Calculator to verify your combination.

What plastics can be welded with an ultrasonic welder?

Our ultrasonic welders are compatible with ABS, PP, PVC, Nylon, PET, and HDPE. For materials like PTFE or LDPE, contact us for customized solutions.