Ultrasonic cutter manufacturer

Hyusonic is a leading Chinese ultrasonic cutter manufacturer, specializing in high-quality ultrasonic cutting machines and ultrasonic blades for both food and industrial applications. Our ultrasonic cutting technology utilizes high-frequency vibrations to precisely disrupt the molecular structure of materials, resulting in cleaner and more accurate cuts compared to traditional cutting methods.

Our ultrasonic cutting solutions are ideal for:

Nonwoven fabric cutting, embossing, and sealing

Precise cutting of food, thermoplastics, and composites

Meeting international standards with CE & ISO9001 certification

Featuring multi-axis drive systems and automated design for improved efficiency

At Hyusonic, we are committed to providing innovative and reliable ultrasonic cutting technology for diverse industries, ensuring precision, quality, and productivity.

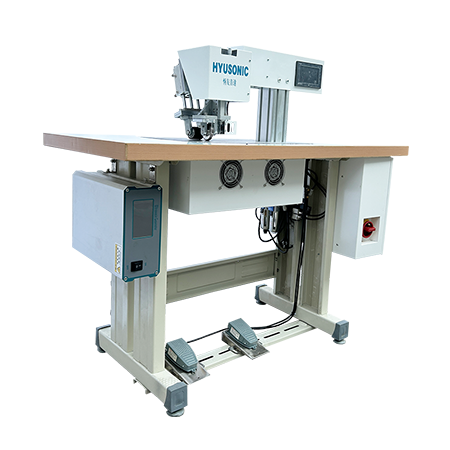

industrial Ultrasonic cutter

Ultrasonic cutter technology is becoming a core process in advanced manufacturing due to its high precision, minimal material damage, and environmental benefits. Ultrasonic cutters are widely used in applications such as composite material processing, precision plastic cutting, and rubber/elastomer processing. They have also enabled the development of innovative applications like ultrasonic lace and ultrasonic sewing, enhancing efficiency and product quality in industrial processes.

Ultrasonic food cutter

Ultrasonic cutter technology is widely used in food cutting applications, including for cakes, meat, energy bars, dough, and more. Compared to traditional cutting methods, an ultrasonic cutter offers several advantages, such as a non-stick blade, non-contact cutting for enhanced safety, high precision, smooth edges, and the ability to cut at temperatures ranging from -30° to 80°. This makes it an ideal choice for precise and efficient food processing.

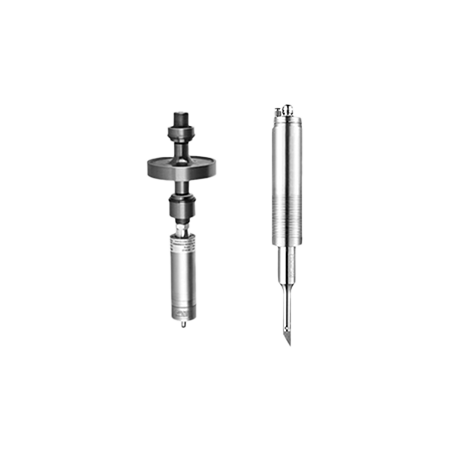

What is an Ultra Sonic Cutter?

An ultrasonic cutter is a precision cutting tool that uses high-frequency ultrasonic vibrations to break the molecular bonds of materials. This results in cleaner, more accurate cuts compared to traditional methods. It’s commonly used for cutting food, thermoplastics, composites, and nonwoven fabrics, offering minimal material waste and faster processing.

how ultrasonic cutter works

Why Choose Our Ultra sonic Cutting Technology?

Choose our ultra sonic cutting technology for its unmatched precision, efficiency, and safety. Our ultrasonic cutters offer non-contact cutting, reducing material damage and waste. With smooth edges, minimal heat generation, and the ability to cut a wide range of materials, including food, plastics, and composites, our technology ensures superior performance. Plus, our solutions are environmentally friendly and cost-effective, making them the ideal choice for industries seeking reliable, high-quality cutting solutions.

Technical advantages

Ultrasonic cutting is used in food cutting, industrial cutting, and non-woven edge banding, and has considerable advantages over traditional cutting processes.

Welding Fast and efficient

Clean and environmentally friendly

Stable welding consistency

Versatile Application Scenarios

Our Value

Direct Factory, More Reliable

As a true manufacturer, we ensure higher quality control, fast response, and professional support. Unlike traders, we offer consistent service from production to after-sales, giving clients a more stable and dependable cooperation experience.

Top Components, Global Support

We use globally trusted parts like Siemens, SMC, and etc. This ensures high machine reliability and makes local replacements easy for international users—saving time and reducing maintenance effort.

Wide Range, Transparent Pricing

From entry-level to high-end models, our ultrasonic welders suit all needs and budgets. Clear classification and pricing let customers select the right configuration with confidence and no hidden costs.

Certified & Patent-Protected Tech

Our machines are CE, ISO-certified and backed by multiple patents. With strong R&D, we deliver safe, innovative, and performance-driven solutions for demanding industries worldwide.

What Our Clients Say

Customer FAQs

What's the difference between ultrasonic and laser cutting?

Mechanism: Ultrasonic cutting uses high-frequency vibrations to slice materials, while laser cutting melts/vaporizes with focused light.

Precision: Lasers offer micron-level accuracy; ultrasonic excels in delicate cuts without heat damage.

Materials: Ultrasonic works best on soft/fibrous materials (food, textiles); lasers handle metals/hard plastics.

Contact: Ultrasonic requires blade contact; lasers are non-contact.

Cost: Ultrasonic systems are typically cheaper to operate and maintain.

How does ultrasonic cutting improve hygiene in food processing?

Ultrasonic food cutting uses food-grade titanium alloy knives that meet FDA safety standards.

Ultrasonic food cutters use vibration instead of blades, eliminating residue buildup and reducing bacterial contamination risks.

Can ultrasonic cutters handle sticky foods like cheese or caramel?

Yes, high-frequency vibrations prevent sticking, enabling clean cuts for soft/sticky foods without refrigeration.

How does ultrasonic lace cutting prevent fabric fraying?

High-frequency vibrations melt and seal fabric edges simultaneously, creating permanent fused edges.

Can ultrasonic cutters create intricate lace patterns?

Yes, with precision CNC-controlled ultrasonic heads for complex designs like floral lace motifs.

Send your inquire now