ultrasonic cutting system

-

High-precision non-contact cutting technology

- Intelligent power dynamic regulation system

- Multi-scenario modular adaptation design

- Industrial-grade durability and low maintenance

- Environmental protection, energy saving and safety protection

description

Hyusonic ultrasonic cutting system uses aviation-grade aluminum alloy and titanium alloy, which greatly extends the service life of the ultrasonic knife. The ultrasonic cutting system can be configured with a handheld module for free and convenient use, or integrated into automated modules to improve cutting efficiency and meet mass production needs. With the advantages of fast cutting speed, high precision, and low energy consumption, the ultrasonic cutting system is mainly used for cutting TPU + carbon fiber multi-layer composites, flexible circuit boards, non-woven fabrics, synthetic fibers, lithium battery separators, silicone catheters, semiconductor films, etc.

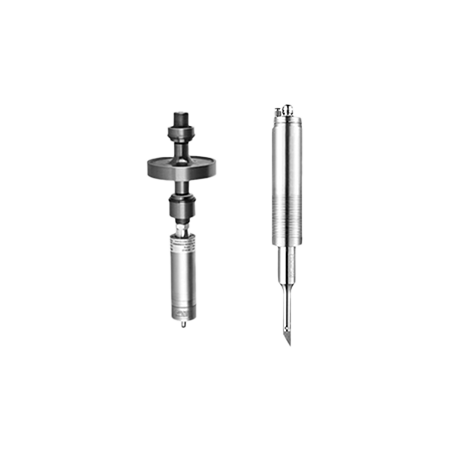

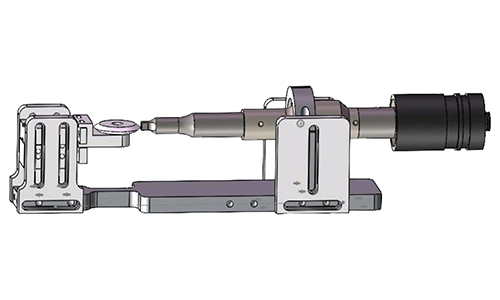

Ultrasonic cutting systems typically include basic components such as ultrasonic knives, ultrasonic generators, and ultrasonic transducers. Automated cutting solutions can be configured according to the cutting requirements of products. Our ultrasonic cutting systems adopt a modular design, which can be freely adapted to automated equipment.

Ultrasonic cutting demonstration

advantages of ultrasonic cutting system

High-Precision Non-Contact Cutting

Cuts with ±0.01 mm precision using tens of thousands of ultrasonic vibrations per second

Prevents material deformation and mechanical tearing

Leaves burr-free, sealed edges, especially in flexible or thin-layer materials

Intelligent Dynamic Power Adjustment

Adapts in real-time to material thickness and hardness

Regulates amplitude (10–60 μm) and cutting pressure

Boosts yield rate to over 99.5%

Energy Efficiency & Clean Operation

Reduces energy consumption by 30% vs. traditional cutting

No heat zone, no fumes, no fabric discoloration

Perfect for medical and cleanroom environments

Modular Design for Flexible Integration

Can be configured into manual, semi-auto or full-auto cutting lines

Fits on workbenches or robotic arms via base-mounted roller wheels

Supports customized solutions for different cutting needs

Applications of Ultrasonic Cutting Systems

Textile Industry: Synthetic drapes, filters, and non-woven fabrics

Medical Devices: Silicone tubing, catheters, sterile packaging

Electronics: FPCs, insulation films, lithium-ion separators

Automotive: Acoustic panels, seat cushions, airbags

Industrial Manufacturing: Laminated foils, coated fabrics, thermal insulators

Why Are Ultrasonic Cutters So Expensive?

Ultrasonic cutting systems are a high-end industrial solution, and pricing reflects the complexity, durability, and precision they offer. Here’s why:

Made with titanium alloy and aviation-grade aluminum, increasing both performance and lifespan

Equipped with intelligent amplitude & power control systems, ensuring consistency across mass production

Integrated piezoelectric ceramic transducers for precise frequency conversion

Modular systems allow for custom automation, increasing R&D and engineering costs

Customer FAQs

What is ultrasonic cutting?

What is ultrasonic cutting theory?

What is the use of ultrasonic cutter?

- Food: cakes, cheese, frozen meats, ice cream

- Non-woven fabrics: masks, surgical gowns

- Biological materials: silicone catheters, hydrogels

- Synthetic fibers: polyester, nylon, spandex

- Multi-layer composites: TPU + fabric composites, carbon fiber prepregs

- Plastic films: PE, PP, PU films

- Flexible circuit boards, lithium battery separators, semiconductor films, etc.