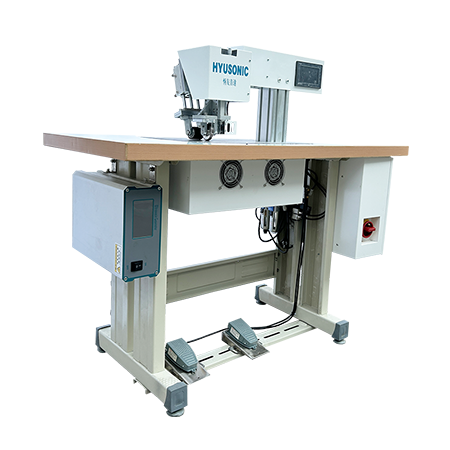

Ultrasonic Sewing Machine for Nonwoven & Textile Bonding

- Wireless & Needle-Free, High Welding Strength

- Single/Multiple Strips Simultaneous Cutting

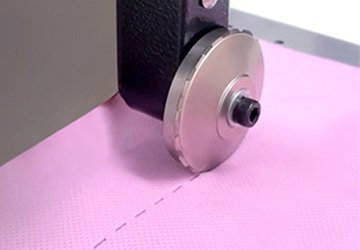

- Smooth Edges, No Roughness

- Burr-Free Cutting, Customizable Patterns

description

Hyusonic ultrasonic sewing machine utilizes high-frequency ultrasonic vibration to generate localized frictional heat at the fabric interface, triggering rapid thermoplastic melting and molecular bonding. This advanced technique replaces traditional stitching or adhesives, enabling seamless edges, hygienic seals, and exceptional tensile strength—up to 30MPa for nylon fabrics.

Available in both lateral drive and vertical drive configurations, our ultrasonic sewing machine is engineered for versatile textile processing, including:

Seaming: Joins synthetic fiber fabrics without needles or threads, delivering strong and watertight seams.

Welding: Fuses multiple fabric layers through ultrasonic energy to create durable, uniform bonds.

Cutting: Performs clean cuts with smooth edges by precisely controlling ultrasonic amplitude and energy.

Embossing: Forms intricate 3D patterns using ultrasonic vibration and custom embossing molds.

Ideal for nonwovens, technical textiles, and synthetic materials, the Hyusonic ultrasonic sewing machine delivers unmatched efficiency, precision, and product quality.

Technical data

| Parameter | Details | |

|---|---|---|

| Technical Data | Power | 1800W-2500W |

| System Frequency | 15kHz/18kHz/20kHz/28kHz /30kHz/35kHz/40kHz |

|

| Pressure | 2000N/3000N/5000N | |

| Weight | 55kg | |

| Generator | Welding Stroke | 10mm/20mm (Customizable) |

| Power Input | AC220V ±10%, 50/60Hz | |

| Weight | 55kg/100kg | |

| Dimensions | Length × Width × Height | 1200mm × 540mm × 1150mm |

Cases

What Our Clients Say

Customer FAQs

What is an ultrasonic sewing machine and how does it work?

An ultrasonic sewing machine uses high-frequency sound vibrations to bond or cut synthetic fabrics without the need for threads or needles. It creates localized heat through friction, melting the fabric layers and forming strong, seamless seams.

What materials can be processed with an ultrasonic sewing machine?

Ultrasonic sewing machines are ideal for thermoplastic materials such as polyester, nylon, polypropylene, nonwovens, and blends. They are widely used in garment production, hygiene products, and technical textiles.

What are the advantages of ultrasonic sewing machines over traditional sewing?

Ultrasonic sewing offers thread-free operation, faster processing, clean and sealed edges, no needle damage, and hygienic, waterproof seams. It also reduces labor and maintenance costs.

Can ultrasonic sewing machines cut and emboss fabrics?

Yes. In addition to bonding, ultrasonic sewing machines can cut fabrics with smooth, sealed edges and emboss 3D patterns using specialized molds—ideal for decorative or functional finishes.

What is the difference between lateral drive and vertical drive ultrasonic sewing machines?

Lateral drive machines apply horizontal ultrasonic energy, offering better handling for curves and patterns. Vertical drive machines apply downward force, ideal for straight seams and consistent welding depth. Both structures serve different textile needs.