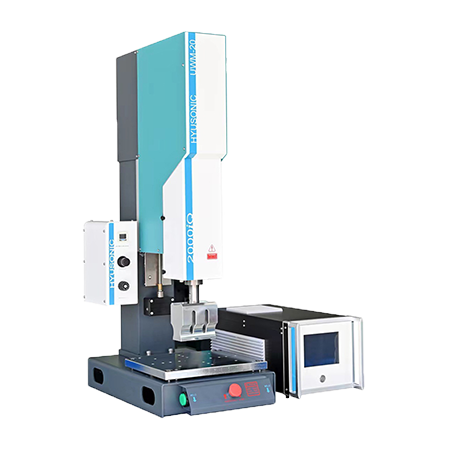

Plastic Ultrasonic Welder ST Series

-

Digital Ultrasonic System

Components Precision-engineered with high-performance acoustic parts . -

Full-Series Modular Design

Scalable configurations for diverse production needs. -

CE & ISO 9001 Certified

Compliant with EU Machinery Directive and global quality standards for risk-free global deployment. -

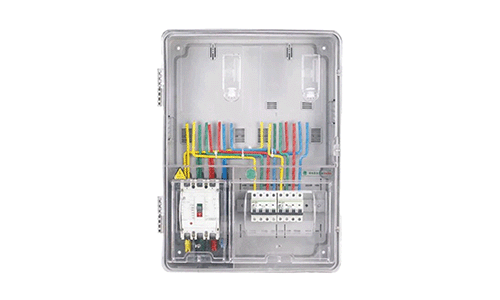

Quality Control Window

Set time threshold to control welding quality

description

The Hyusonic plastic ultrasonic welder ST Series is a cost-effective standard ultrasonic plastic welding machine designed for simplicity and flexibility. Featuring a digital ultrasonic system and modular design, it allows quick component swaps and adapts seamlessly to your workspace—configure it as a floor-standing unit for industrial setups or a compact benchtop system for small workshops. With two welding modes (time/energy) and one-trigger operation, it simplifies the task of bonding thermoplastics such as ABS, PP, or PS parts. The 8800ST also includes automatic alarms and adjustable time/energy limits to maintain basic quality control, making it ideal for non-critical plastic products such as consumer goods, low-volume packaging, or prototypes where ultra-high precision isn’t required.

Why ST series Stand Out

Intelligent Monitoring

Equipped with professionally designed automatic welding monitoring, defective product detection, multiple welding modes, and trigger methods, it meets the requirements of most welding scenarios.

Stable Ultrasonic System

The ST series, with its optimized structure and stable ultrasonic system, suits standard thermoplastic welding/tube sealing applications. It welds PP/ABS/PVC/PE materials, delivering fine craftsmanship and high cost-performance.

Price & Service

HYUSONIC, a Chinese ultrasonic welding machine manufacturer, ensures first-tier quality via excellent supply chains at favorable prices, offering comprehensive trial welding, training, warranty and after-sales support.

Technical data

| Parameter Category | Details |

|---|---|

| Operating Frequency | 15kHz / 20kHz / 28kHz / 30kHz / 35kHz / 40kHz |

| Input Voltage | 220V ± 10%, 50/60Hz, Single-Phase |

| Output Power | 800W / 1200W / 2500W / 2600W / 3000W / 4000W / 5000W / 6000W / 10000W |

| Welding Range/Accuracy | – Energy Range: 1–9999 Ws – Welding Time: 0.01s–10s |

| Drive Requirements | – Pressure: 2000–5000N (Customizable) – Stroke: 75mm (Customizable) – Acoustic Component Fixation: Flexible Joint / Rigid Joint (Optional) |

| Dimensions | Frame Size (W × D × H): 400mm × 700mm × 1450mm |

Why choose ultrasonic welding plastic process

For industries needing plastic welding/joining, with options like adhesives, hot melting, spin welding, laser welding, infrared welding, etc.—why choose ultrasonic plastic welding specifically?

1. Safe and clean. For the food, cosmetics, and medical industries where product safety is critical, adhesives or common hot-melt processes emit toxic fumes. In contrast, ultrasonic welding produces no chemical gases. It is used for welding food plastic packaging, sealing cosmetics ends and closure foils, and joining medical filters and catheters, meeting FDA standards.

2. Mass production and yield rate. Products in many industries need to evaluate mass production speed. Ultrasonic welding typically has a single-cycle speed of 0.1-1s, with its speed and yield rate significantly outperforming other welding methods.

3. Sealing performance and special materials. For applications needing absolute weld strength—e.g., meter boxes, where traditional screw fastening fails to prevent illegal opening, ultrasonic welding eliminates this risk. In food and cosmetics sectors, it quickly joins metal foils to plastics for packaging sealing, ensuring tightness while enabling easy consumer opening.

welding cases

What Our Clients Say

Customer FAQs

How much does an industrial plastic ultrasonic welder cost?

The price of ultrasonic welding machine depends on the component structure of ultrasonic system, welding requirements and precision to be achieved. The general price ranges from several thousand to hundreds of thousands. If you need ultrasonic welding equipment, choose hyusonic to request a quote.

Why is my ultrasonic metal welder producing inconsistent weld joints?

Check for misaligned tooling, uneven pressure, or frequency drift. Calibrate welding time (0.01s-10s range) and verify energy output (1ws-9999ws).

What are the cost benefits of switching from laser welding to ultrasonic metal welding?

Ultrasonic welding reduces energy costs (no consumables), eliminates shielding gas, and operates at lower voltages (AC220V), saving 30-50% in long-term expenses.

Can ultrasonic welders join dissimilar plastics?

Yes, but only compatible pairs (e.g., ABS to PC). Use our Material Compatibility Calculator to verify your combination.

What plastics can be welded with an ultrasonic welder?

Our ultrasonic welders are compatible with ABS, PP, PVC, Nylon, PET, and HDPE. For materials like PTFE or LDPE, contact us for customized solutions.