What Materials Can Be Ultrasonically Welded?

Publish Data:2025.8.4 Author: Hyusonic

Introduction:

Ultrasonic welding has become an essential technology in various industries such as automotive, electronics, medical, and packaging. This high-tech process uses ultrasonic vibrations to join materials together without the need for adhesives or mechanical fasteners. It’s widely praised for its precision, speed, and energy efficiency. But which materials can be ultrasonically welded? In this blog, we will explore the science behind ultrasonic welding, explain why certain materials are ideal for this process, and detail which materials are commonly welded using ultrasonic technology.

What is Ultrasonic Welding?

Unlike traditional welding methods, which typically rely on heat from an external source such as an arc or flame, ultrasonic welding directly generates heat at the weld interface, making the process both faster and more energy-efficient.

Ultrasonic welding is used in many industries, including:

Automotive: For welding plastic parts like dashboards, door panels, and fuel tanks.

Electronics: For joining wires, battery packs, and other small components.

Medical Devices: For creating plastic housings and other sterile components.

Packaging: For sealing films and containers in packaging.

How Does Ultrasonic Plastic Welding Work?

Basic Principle

Thermoplastic Polymer Structure

To understand why thermoplastics can be welded using this technique, we need to explore their molecular structure. Thermoplastics consist of long polymer chains that are flexible. These polymers can soften and melt when heat is applied, but unlike thermosetting plastics, they don’t undergo a chemical change. The ability of these polymers to soften and flow under heat makes them ideal candidates for ultrasonic welding.

When ultrasonic vibrations are applied, the heat generated causes the molecular chains to move, interlock, and create a strong bond between the two plastic parts.

Energy Focus and Control

The ultrasonic transducer converts electrical energy into high-frequency mechanical vibrations. These vibrations are concentrated at the welding point, ensuring that heat is generated exactly where it is needed. This highly localized heating allows for very precise control of the welding process.

In addition to heat, pressure is applied to the joint area, and the welding time is precisely controlled to ensure a reliable, high-quality bond. The combination of vibration, pressure, and time is critical to achieving the optimal weld.

What Materials Can Be Ultrasonically Welded?

Thermoplastics

Thermoplastics are by far the most commonly used materials in ultrasonic welding. These materials have unique properties that make them ideal for the process.

What Are Thermoplastics?

Thermoplastics are a type of polymer that can be melted and reformed multiple times without undergoing any significant chemical changes. The molecular structure of thermoplastics allows them to soften when heated and solidify upon cooling. This characteristic is vital for ultrasonic welding because it means the material can flow under heat, allowing the ultrasonic vibrations to create a strong bond between two plastic parts.

Why Thermoplastics Can Be Ultrasonically Welded

Thermoplastics can be ultrasonically welded because their molecular chains are long and flexible, allowing them to move when heat is applied. The ultrasonic vibrations generate localized heat at the weld interface, causing the plastic to soften and fuse together. Once the energy is removed, the plastic cools and solidifies, forming a strong, durable bond between the parts.

Common Thermoplastics for Ultrasonic Welding

Polypropylene (PP)

Polypropylene is a widely used thermoplastic that is easily welded using ultrasonic technology. It is commonly found in automotive, packaging, and medical device applications.Polyethylene (PE)

Polyethylene, especially high-density polyethylene (HDPE), is another common thermoplastic that can be welded with ultrasonic energy. It is used in applications like packaging, medical containers, and pipes.Acrylonitrile Butadiene Styrene (ABS)

ABS is a tough and impact-resistant material often used in automotive and electronics industries. It is well-suited for ultrasonic welding due to its ability to melt and fuse under ultrasonic vibrations.Polyvinyl Chloride (PVC)

PVC is used in a variety of applications, including pipes, medical devices, and electrical insulation. Its ability to weld with ultrasonic energy makes it ideal for creating strong, reliable joints.Polycarbonate (PC)

Known for its clarity and strength, polycarbonate is used in applications where transparency is important, such as in eyewear and optical lenses. Ultrasonic welding is an effective method for joining polycarbonate parts.Polyamide (Nylon)

Nylon is commonly used in the automotive and textile industries. It is known for its strength and durability, and ultrasonic welding can be used to bond nylon components effectively.Polystyrene (PS)

Polystyrene is a versatile thermoplastic used in packaging, disposable containers, and medical applications. Ultrasonic welding is often used to join polystyrene parts quickly and efficiently.Polyetheretherketone (PEEK)

PEEK is a high-performance polymer used in demanding applications such as aerospace and medical devices. Although more challenging to weld, ultrasonic welding can still be used effectively for certain PEEK applications.

Other Materials

While ultrasonic welding is primarily used for thermoplastics, it can also be applied to certain metals and composite materials under specific conditions.

Metals: Ultrasonic welding can be used for some metals like aluminum and titanium, particularly in applications such as battery packs, electrical components, and wire bonding.

Composites: Some fiber-reinforced plastics or composite materials can be ultrasonically welded, though the process requires careful control to avoid damaging the fibers.

Why Are Thermoplastics Ideal for Ultrasonic Welding?

Molecular Structure and Heat Sensitivity

The molecular structure of thermoplastics is the key to their ability to be welded using ultrasonic technology. These polymers have long, flexible chains that can slide past one another when heat is applied. This property allows them to soften and form strong, cohesive bonds under the right conditions.

Advantages of Thermoplastics in Ultrasonic Welding

- Fast Processing Time:

Ultrasonic welding of thermoplastics is a rapid process, ideal for mass production environments where speed and efficiency are critical. - No Need for Additional Materials:

Unlike other welding methods, ultrasonic welding does not require adhesives, solvents, or other bonding agents, which makes it an environmentally friendly option. - Strong and Reliable Joints:

The bond created by ultrasonic welding is strong, durable, and resistant to stress, making it suitable for a wide range of applications.

Factors That Influence Ultrasonic Welding in Plastics

- Material Thickness:

Thicker materials require more energy to weld, while thinner materials can be welded more quickly. The welding parameters must be adjusted accordingly. - Material Composition:

Materials with higher filler content, such as glass-filled polymers, may require different ultrasonic settings to achieve the optimal weld. - Surface Finish:

Smooth surfaces typically result in better welds compared to rough surfaces, as the energy is more evenly distributed.

Benefits of Ultrasonic Welding for Thermoplastics

Speed and Efficiency:

The process is extremely fast, reducing cycle times and allowing for high-volume production.Precision and Cleanliness:

Ultrasonic welding is a clean process that doesn’t require additional adhesives or solvents, ensuring a more sterile and precise joint.Energy Efficiency:

Less energy is required compared to traditional welding methods, making it an eco-friendly and cost-effective choice.

Challenges and Limitations

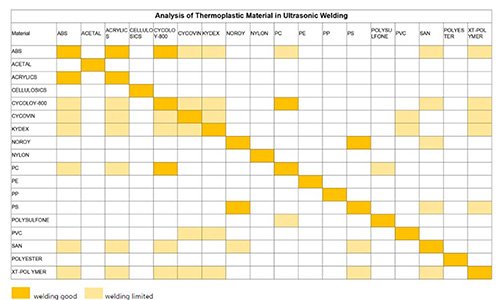

Material Compatibility:

Not all materials can be welded with ultrasonic technology. Some plastics may not respond well to ultrasonic vibrations, leading to poor welds.Weld Quality:

If welding parameters are not optimized, issues like weak joints or incomplete welds can occur.Cost of Equipment:

Although ultrasonic welding offers high-quality results, the initial investment in equipment can be relatively high.

Conclusion:

Ultrasonic welding is a highly efficient and effective process for joining thermoplastics. Its speed, precision, and ability to create strong, reliable bonds make it an ideal choice for industries that require quick, high-quality welding. By understanding the materials that can be welded and the science behind the process, manufacturers can optimize their production lines for better efficiency and cost-effectiveness.

For industries using plastics, ultrasonic welding presents an excellent solution for ensuring strong, reliable, and environmentally friendly bonds. Whether you are manufacturing automotive parts, medical devices, or consumer electronics, ultrasonic welding can provide a significant advantage.