Ultrasonic Welding Plastic Design Guidelines for Strong, Durable Joints

Publish Data:2025.12.03 Author: Hyusonic

If you’re designing plastic parts for ultrasonic welding, you already know that getting the joint right can make or break your whole assembly. But did you realize that up to 50% of weld failures come down to poor design—before you even start the machine? With the right ultrasonic welding plastic design guidelines, you can slash cycle times, boost weld strength, and eliminate costly rework. This isn’t just theory—these are proven strategies that real manufacturers rely on to scale faster and cleaner production. In this post, you’ll discover how to optimize part geometry, material selection, and joint design so every weld comes out reliable, airtight, and ready for high-volume success. Let’s dive in and unlock the full potential of ultrasonic welding with insights straight from the experts at HYUSONIC.

Fundamentals of Ultrasonic Welding: How Design Drives Success

Ultrasonic welding is a fast, clean, and reliable way to join plastic parts. But did you know that the design of those parts plays a key role in making every weld strong and consistent? It’s true—good plastic joint design for ultrasonic welding can mean the difference between a perfect bond and costly rejects.

At its core, ultrasonic welding uses high-frequency vibrations to melt the interface of thermoplastic parts. The melted material forms a solid joint as it cools, no adhesives or fasteners needed. However, to get this right, the design must guide energy precisely where it’s needed.

Here’s how design drives success:

- Energy Director Guidelines: Small features like tapered ridges concentrate ultrasonic energy, ensuring quick, clean fusion.

- Material Compatibility: Selecting thermoplastics that respond well to ultrasonic welding affects how heat is generated and retained.

- Joint Geometry: Proper part geometry supports efficient energy transfer and consistent weld strength.

In short, ultrasonic welding isn’t just about powerful machines—it’s about smart design choices that control how energy flows and where fusion happens. Overlooking design details can cause improper melting, weak joints, or excessive flash. So, focusing on design fundamentals sets you up for smooth manufacturing and quality results right from the start.

Material Selection: Choosing Thermoplastics for Optimal Weldability

Selecting the right material is crucial for successful ultrasonic welding. Thermoplastics are the go-to choice because they soften when heated, allowing a strong bond without melting the entire part. When picking plastics, consider amorphous vs semi-crystalline plastics—amorphous types like ABS or polycarbonate generally weld more easily because they soften uniformly. Semi-crystalline plastics, such as polypropylene or nylon, require more precise control of ultrasonic welding parameters due to their distinct melting behaviors.

Keep in mind the plastic’s compatibility with ultrasonic welding. Not all thermoplastics respond equally, so it’s essential to consult detailed guides on material selection ultrasonic bonds to avoid weak joints or part damage. Good weldability also depends on factors like moisture content and additives in the plastic.

When designing parts, refer to energy director guidelines—these small features help concentrate ultrasonic energy for better weld strength. Selecting plastics compatible with your welding process improves efficiency and reduces troubleshooting.

For a comprehensive overview of the plastics that work best with ultrasonic welding, check out our detailed resource on materials that can be ultrasonically welded and explore our range of reliable ultrasonic plastic welders designed to optimize weld quality.

Essential Joint Design Strategies: Building Bonds That Last

When it comes to plastic joint design for ultrasonic welding, the right joint type and energy director placement make all the difference in weld strength and durability. Choosing from common joint styles like scarf joints, butt joints, and projection welding plastics helps match your product’s needs for strength, appearance, and sealing.

Key design tips include:

- Energy Directors: These small, triangular ridges focus ultrasonic energy to create a precise melt zone. Proper energy director geometry, size, and location are crucial—too large, and you risk flash control issues, too small, and the weld might be weak.

- Butt Joint Variations: While butt joints are simple, variations like adding support ribs or standoffs can improve alignment and consistency during welding.

- Material Compatibility: Design your joint with thermoplastic weld compatibility in mind, considering how amorphous vs semi-crystalline plastics behave during welding.

- Avoid Thin Walls: Thin or uneven walls near the joint can cause inconsistent welds or part deformation.

- Seal Designs: For applications needing hermetic seal ultrasonic design, joint precision and uniform contact areas are critical.

Focusing on these joint design strategies ensures that your ultrasonic plastic welder achieves reliable, strong welds that last. For hands-on solutions, our 2000iQ series ultrasonic plastic welder supports advanced joint designs with precise process control, helping you build consistent quality parts.

Explore our 2000iQ series ultrasonic plastic welder for high-precision joint welding capabilities tailored for your application.

Part Geometry and Tooling Considerations: Avoiding Design Pitfalls

When designing plastic parts for ultrasonic welding, part geometry plays a huge role in ensuring consistent weld quality and avoiding common issues. Proper part geometry helps concentrate the ultrasonic energy where it’s needed, reducing weld time and improving bond strength.

Key geometry tips include:

- Energy directors: These small, triangular or rib-like features focus ultrasonic vibrations to initiate melting quickly. Correct sizing and placement are critical—too large can cause excess flash; too small may prevent proper bonding.

- Joint type: Butt joints, projection welding, or tongue-and-groove designs each demand different considerations for proper horn contact and consistent weld area.

- Uniform wall thickness: Keeping parts uniformly thick near the weld zone prevents uneven melting or overheating.

- Avoid sharp corners: Rounded edges reduce stress concentrations and help maintain consistent horn contact.

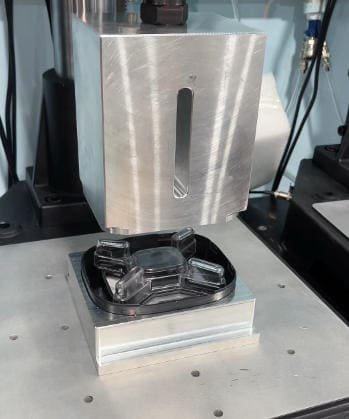

Ultrasonic horn tooling also needs to match the part design perfectly. The horn shape and surface finish impact energy transmission and weld consistency. For complex geometries or tight tolerances, custom ultrasonic horn tooling may be necessary to optimise the weld area and reduce cycle times.

To avoid common design pitfalls, collaborate early with your ultrasonic equipment supplier to ensure your part geometry and tooling align perfectly. You can explore options for tailored ultrasonic welding solutions through advanced ultrasonic system technologies designed to optimise energy delivery and assembly precision.

Keeping these design and tooling factors in check will set your ultrasonic welding process up for repeatable success and strong, reliable plastic joints.

Process Parameters and Optimization: Fine-Tuning for Peak Performance

Optimising ultrasonic welding parameters is key to creating strong, consistent plastic joints. The main factors to control include:

| Parameter | Description | Impact on Weld Quality |

|---|---|---|

| Weld Time | Duration of horn vibration | Too short = weak bond; too long = flash or part damage |

| Amplitude | Horn vibration intensity | Higher amplitude increases heat but may deform parts |

| Pressure | Force applied during welding | Proper pressure ensures good fusion without crushing parts |

| Hold Time | The time part is held after the vibration stops | Allows joint cooling and solidifying |

| Trigger Force | Initial force to start welding | Prevents premature horn activation |

Fine-tuning these parameters depends on your plastic joint design for ultrasonic welding and the specific thermoplastic weld compatibility. Materials like amorphous plastics require different settings than semi-crystalline types, so adjustments matter.

For better results:

- Use energy director guidelines—small triangular ribs that focus energy and improve efficiency.

- Minimise flash control by balancing amplitude and pressure.

- Adjust for part geometry for sonic assembly; thicker sections require more energy.

- Test weld strength using standards like ASTM Weld Strength Testing to validate optimisation.

Our ultrasonic plastic welding machines offer precise control over all these parameters, allowing you to dial in settings for peak performance. For insights on how the ultrasonic welding process works and fits into scalable production, check our detailed explanation of the working process. This helps ensure your designs and machinery work hand in hand for the best results.

Industry Applications and Best Practices: Real-World Implementation

Ultrasonic welding of plastics is widely used across industries, from automotive and medical devices to electronics and packaging. Each sector leverages this fast, clean, and reliable joining method to meet specific needs like creating hermetic seals or ensuring strong, contamination-free bonds. For instance, in medical device manufacturing, ultrasonic welding enables precise assembly without introducing adhesives, which is critical for sterility and safety.

To get the best results, follow proven plastic joint design for ultrasonic welding and energy director guidelines. These help maximise weld strength and minimise defects such as flash or incomplete fusion. Consider the type of plastic—whether amorphous or semi-crystalline—as material behaviour influences thermoplastic weld compatibility and overall joint integrity.

In everyday production, controlling ultrasonic welding parameters like amplitude, pressure, and weld time is essential. Consistent setup improves repeatability and yield, especially in scalable ultrasonic production designs. Using the right ultrasonic horn tooling tailored for your part geometry enhances energy transfer and helps avoid common pitfalls that cause weld inconsistencies.

Regular weld strength testing (ASTM) should be part of quality assurance to ensure joints meet performance standards. Keep an eye on flash control in plastic welding, as excessive flash can require additional finishing steps and increase costs.

For those looking to upgrade or invest in reliable equipment, checking out the top ultrasonic plastic welder manufacturers can help you find machines suited for your application and budget. Partnering with a trusted supplier ensures you get expert support for optimising designs and troubleshooting ultrasonic assembly issues.

Implementing these best practices makes ultrasonic plastic welding a robust solution for high-volume, precise, and clean assembly tasks.