Ultrasonic Welding in the Apparel Industry: Benefits and Uses

Publish Data:2025.12.4 Author: Hyusonic

How Ultrasonic Welding Actually Works in Garment Production

Ultrasonic welding in apparel is a clever process that uses high-frequency vibrations to join fabrics without thread or needles. Here’s how it works in simple terms:

- High-frequency vibration: The ultrasonic machine creates ultrasonic waves—really fast vibrations—usually around 20,000 times per second.

- Frictional heat: When these vibrations meet the fabric, they generate frictional heat right at the joining point.

- Molecular bonding: That heat softens or melts the synthetic fibers just enough to fuse them together on a molecular level. As it cools, it forms a strong, seamless bond.

This threadless sewing approach relies on four key components:

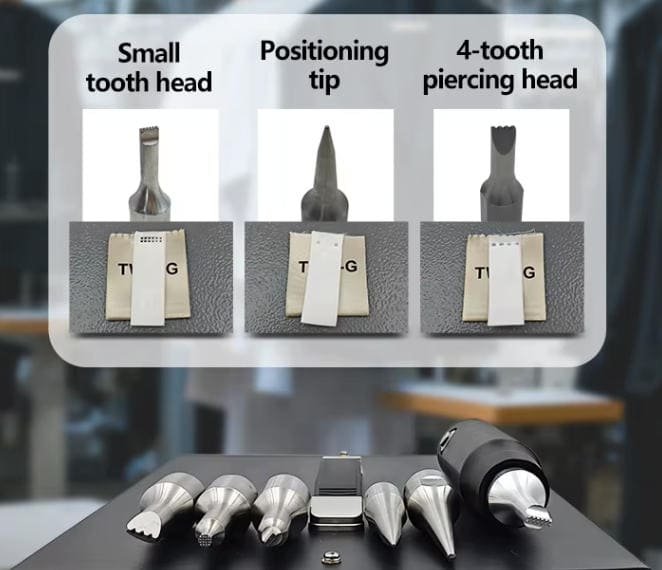

- Anvil wheel: Holds and supports the fabric firmly during welding.

- Horn: The vibrating tool that applies pressure and transmits ultrasonic energy to the fabric.

- Generator: Powers the horn and controls the frequency and amplitude of the vibrations.

- Pattern roller: Adds decorative or functional embossed patterns to the welded seam, giving clean, attractive finishes.

Together, these components enable fast, clean, and durable fabric joining, making ultrasonic welding an innovative alternative to traditional sewing in garment production.

8 Core Benefits That Make Ultrasonic Welding Irreplaceable in Modern Apparel

Ultrasonic welding has transformed garment production with a set of powerful benefits that traditional sewing just can’t match. Here’s why it’s becoming essential in the apparel industry:

| Benefit | What It Means for Your Apparel |

|---|---|

| Seamless & Threadless | No stitches or thread — clean, smooth garment surfaces |

| 100% Waterproof & Windproof | Perfect sealed seams that keep out water and wind |

| Up to 70–80% Faster | Speed up production dramatically compared to traditional sewing |

| Lower Labor & Consumables Costs | Less manual work, zero thread waste, fewer parts to buy |

| Cleaner Cut-and-Seal Edges | Edges won’t fray or require overlock stitching |

| Stronger Bonds Than Stitching | Bonds hold up better under stretching and repeated washing |

| Eco-Friendly Process | No glue, no thread waste, and lower energy use than RF welding |

| Enables Creative Designs | Adds lace welding, 3D textures, and embroidery-like patterns |

This means ultrasonic welding isn’t just about faster seams — it’s about elevating quality, cutting costs, and opening exciting new design opportunities with sustainable benefits included. For those curious about the technical side, you might find our guide on ultrasonic welding plastic design guidelines for strong durable joints helpful in understanding how bonding strength is achieved.

In short, ultrasonic welding offers a modern solution that boosts performance and sustainability in apparel production while opening doors to new styles no traditional sewing can match.

Real-World Applications in Today’s Apparel Segments

Ultrasonic welding has found a solid place across various apparel categories thanks to its seamless, waterproof, and strong bonding capabilities. In outdoor and performance wear, it creates Gore-Tex®-like taped seams that keep water and wind out without bulk. For activewear and compression garments, ultrasonic bonding delivers stretch-friendly, durable seams that stand up to intense movement and repeated washes.

In lingerie and seamless underwear, this technology offers smooth, threadless edges that boost comfort by eliminating itchy seams. The method also shines in medical and protective clothing, where precise, hygienic bonding is critical for safety and durability.

Luxury ready-to-wear brands use ultrasonic welding to achieve immaculate finishes and invisible hems that elevate product appeal without sacrificing strength. Even children’s wear benefits, with softly sealed edges that avoid irritation, making garments safer and more comfortable.

This versatile technology is reshaping apparel manufacturing, enabling high-quality, innovative designs that meet modern consumer demands for comfort, performance, and style. For precision and durability in every garment, ultrasonic welding systems like the HYUSONIC ultrasonic blade deliver reliable results across all these segments.

Ultrasonic Welding vs Traditional Sewing & Other Bonding Methods

Here’s a quick comparison to show how ultrasonic welding stacks up against traditional sewing and other common bonding methods used in apparel production:

| Feature | Ultrasonic Welding | Traditional Sewing | Heat Press Adhesive | RF Welding |

|---|---|---|---|---|

| Speed | 70–80% faster than sewing | Slower, labor-intensive | Moderate | Moderate |

| Strength | Stronger bonds, especially under stretch & wash | Strong but can weaken over time | Weaker, adhesive may peel | Strong, but limited fabric types |

| Waterproof | Completely waterproof, sealed seams | Seams can allow water in | Usually waterproof | Waterproof |

| Cost per seam | Lower labor + no thread costs | Higher labor and thread costs | Material costs can add up | Moderate |

| Waste | Minimal (no thread or glue waste) | Thread waste and needle breakage | Waste from adhesives | Moderate waste |

| Aesthetic | Clean, seamless, no visible thread | Visible stitching, bulkier | Can appear glued or plasticky | Usually neat but limited patterns |

| Sustainability | Eco-friendly: no thread, low power | Uses polyester threads, higher energy | Adhesives may release VOCs | Higher energy consumption |

Ultrasonic welding’s combination of speed, strength, and eco-friendly seamless construction makes it a clear choice for innovative, cost-effective apparel manufacturing. For a closer look at how it works compared to other welding methods, check out this detailed comparison of ultrasonic welding vs resistance welding.

If you want to see how ultrasonic welding machines outperform other fabric bonding tech, especially on durable and delicate materials, you can also explore our section on ultrasonic sewing machines.

Proven Cost Savings & ROI Examples

Ultrasonic welding in apparel brings clear cost advantages that quickly show up on the bottom line. Many mid-size factories see a typical payback period between 6 and 14 months after installing ultrasonic welding machines. This fast return happens because of significant reductions in several expense areas.

Key savings include:

- Thread consumption drops dramatically since seams are made without any thread, cutting costs on supplies.

- Needle breakage is nearly eliminated, reducing both repair expenses and production downtime.

- Maintenance downtime for machines also drops, thanks to fewer moving parts and less frequent servicing compared to traditional sewing equipment.

These savings combine to create a strong, ongoing ROI. Case studies show manufacturers improving efficiency and slashing costs while maintaining or even boosting product quality. Investing in high-performance ultrasonic welding systems, like those offered by HYUSONIC ultrasonic welding machines, ensures reliable, cost-effective garment production that keeps factories competitive in the US market.

Sustainability Angle – Why Ultrasonic Is the Future

Ultrasonic welding shines as a sustainable choice for apparel manufacturing. By eliminating the need for sewing thread, it helps save millions of meters of polyester thread each year—significantly cutting down plastic waste. Plus, ultrasonic welding uses less energy compared to heat presses or adhesive bonding lines, making it a greener option for factories aiming to lower their carbon footprint.

Another big eco win is that ultrasonic bonding leaves no needle holes in fabrics. This means recycled textiles can be reused with better quality and fewer defects since the fabric’s integrity stays intact. As more brands push for sustainable garment manufacturing, ultrasonic welding supports these goals by reducing waste, energy use, and enabling circular fashion through improved fabric recyclability.

If you’re interested in how ultrasonic technology compares to other fabric bonding methods, check out our detailed guide on ultrasonic sealing vs heat sealing for a closer look at their sustainability impact.

Choosing the Right Ultrasonic Welding Solution for Your Factory

Picking the right ultrasonic welding machine for your apparel production starts with understanding your factory’s specific needs. Here are key specs to consider:

- Machine Type: Single-head systems are ideal for smaller batches or detailed work, while continuous rotary systems boost speed and efficiency in high-volume production.

- Welding Power & Frequency: Ensure the machine delivers consistent energy output to handle various fabric types without damage.

- Pattern Variety: Look for machines that offer customizable pattern rollers to create different seam styles and decorative effects.

- Durability: Choose equipment built for long-term, heavy factory use with minimal downtime.

- Service & Support: Reliable customer service and easy access to maintenance parts can save money and keep your line running smoothly.

HYUSONIC machines shine in all these areas. Their ultrasonic generators deliver precise, consistent performance, while advanced horns and anvil wheels provide cleaner, stronger bonds. Plus, HYUSONIC offers a wide range of welding patterns that open up new design possibilities. You can explore the details of their cutting-edge ultrasonic welding generator systems to better understand the tech powering these machines.

To help you decide, HYUSONIC also provides a quick ROI calculator that estimates your savings based on your production scale and material costs. This helps you see exactly when your investment pays off—usually within just 6 to 14 months for mid-size factories.

With the right ultrasonic welder, you’ll boost productivity, reduce costs, and step confidently into the future of sustainable, no-thread sewing technology.

Frequently Asked Questions About Ultrasonic Welding in Apparel

Is ultrasonic welding safe for all fabrics?

Ultrasonic welding works best with synthetic and thermoplastic fabrics like polyester, nylon, and spandex, which respond well to heat-free fabric joining. Natural fibers like cotton or wool don’t bond as effectively, but blends often do. For delicate or mixed materials, specialized settings and machine adjustments can help avoid damage.

Can ultrasonic welding replace sewing completely?

In many cases, yes. Ultrasonic bonding offers seamless garment technology that eliminates thread and stitching lines, making it ideal for activewear, lingerie, and waterproof clothing. However, some heavy-duty or complex garments may still require traditional sewing in combination with ultrasonic welding for optimal strength.

What fabrics work best with ultrasonic welding?

Fabrics with thermoplastic properties—such as polyester, nylon, spandex, and laminated materials—are perfect. These materials melt and bond under ultrasonic vibration without fabric damage. Fabrics designed for waterproof seam sealing, like Gore-Tex® alternatives, are prime candidates.

How loud is the ultrasonic welding machine?

While ultrasonic machines generate high-frequency vibrations, their noise levels are generally moderate and comparable to common industrial equipment. Modern ultrasonic welders are designed with noise reduction features, ensuring a more comfortable work environment.

What about maintenance and spare parts availability?

Maintenance is straightforward since ultrasonic welders have fewer moving parts than sewing machines. Routine checks and horn or anvil wheel replacements keep machines running smoothly. Leading manufacturers, like HYUSONIC, provide reliable spare part availability and responsive service to minimize downtime and keep production efficient.

For a detailed look into different types of ultrasonic welding technology, including full and semi-wave systems, check out this guide on full vs semi-wave ultrasonic welding. If you’re ready to invest, our overview of the best ultrasonic welder manufacturers can help you choose the right equipment for your apparel production needs.