Optional Configurations

- Servo-Driven Precision Control

- MES Integration (Industry 4.0 Ready)

- Automated Load/Unload Systems

- Vision-Based Inspection & Recognition

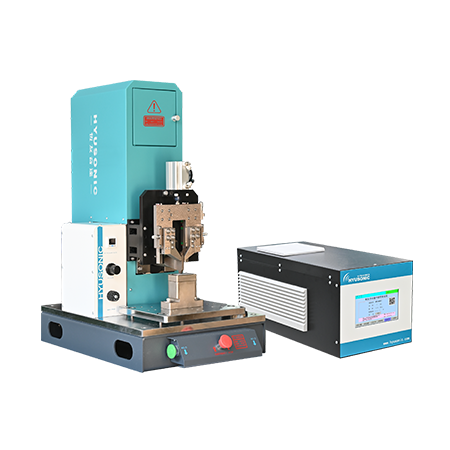

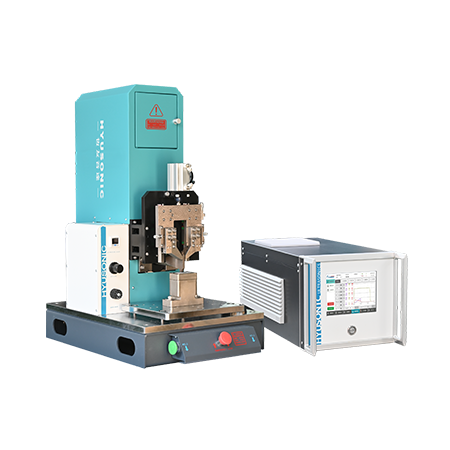

Ultrasonic Metal Welding Machine iQ Series

-

European Imported Ultrasonic Components

It adopts German imported circuit board components and rigid joint connection to achieve high-precision control and stability. -

Full-Series Modular Design

Scalable configurations for diverse production needs. -

CE & ISO 9001 Certified

Compliant with EU safety standards and international quality management. -

6 Welding Modes & 4 Trigger Modes

Programmable logic for complex applications (Time/Energy/Peak Power/Absolute Distance/Relative Distance/Ground Detect modes). -

Real-Time Monitoring & Quality Control

Dynamic data tracking (pressure/power) with automated fault alerts.

description

The IQ Series Ultrasonic Metal Welding Machine integrates a German-engineered ultrasonic system and intelligent industrial automation technology to provide unparalleled precision for high-risk industries such as automotive, aerospace, and energy storage. Designed for wires, terminals, busbars, and battery pole pieces, the equipment achieves a tolerance of ±0.05 mm through real-time weld analysis and multi-dimensional adjustable thresholds to ensure zero-defect production.

Why Choose Ultrasonic metal Welding machine IQ Series

German Stable Ultrasonic System

We have in-depth technical cooperation with Germany and use important components of ultrasonic systems that meet international standards to ensure the stability and quality of the machines.

Latest Control Technology

The IQ series ultrasonic metal welder feature intelligent QC monitoring/alarm, Industry 4.0 integration, and multi-dimensional threshold control for 0.01mm precision, meet high-quality inspection standards.

Price & Service

HYUSONIC, a Chinese ultrasonic welding machine manufacturer, ensures first-tier quality via excellent supply chains at favorable prices, offering comprehensive trial welding, training, warranty and after-sales support.

Technical data

| Parameter | Specifications/Range | |

|---|---|---|

| Technical Data | Machine Power | 800W / 1200W / 2000W / 2500W / 3000W / 3600W / 4000W / 5000W / 6000W / 10000W |

| Frequency | 20kHz / 28kHz / 30kHz / 35kHz / 40kHz | |

| Power Input | AC220V ±10%, 50Hz/60Hz | |

| Pressure | 2000 – 5000N (customizable) | |

| Welding Stroke | 75mm / 100mm (customizable) | |

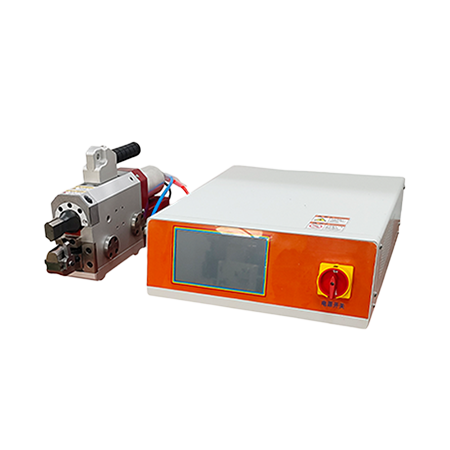

| Operation Type | Benchtop / Floor-integrated type | |

| Weight | 55KG / 160KG | |

| Welding (Range/Precision) | Energy Range | 1ws – 9999ws |

| Adjustable Displacement Precision | 0.01mm | |

| Welding Time | Range: 0.01s – 10s | |

| Dimensions | Frame (L×W×H) | 400mm × 680mm × 2010mm |

| Control Box (W×D×H) | 265mm × 580mm × 255mm |

welding cases

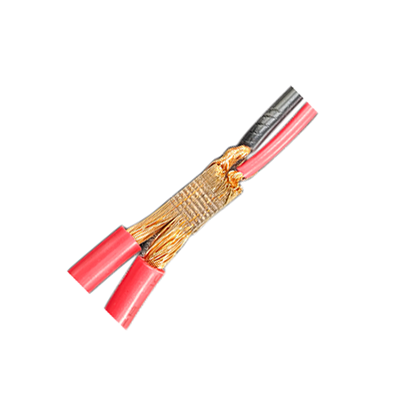

Ultrasonic Metal Welding for EV Battery Tabs

Ultrasonic metal welding machines are widely used in lithium battery manufacturing, especially for welding aluminum or copper battery tabs. The IQ series offers high consistency, low resistance joints, and no need for filler materials.

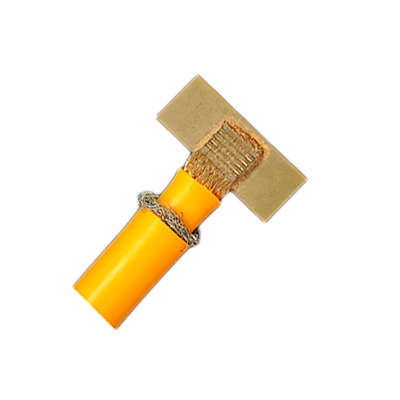

Wire Harness and Terminal Welding

Ultrasonic welding is ideal for joining stranded wires and terminals. Unlike crimping or soldering, ultrasonic welding ensures strong, oxidation-free joints.

Customer FAQs

What factors determine the optimal power selection for an ultrasonic metal welding machine?

What are the cost benefits of switching from laser welding to ultrasonic metal welding?

Ultrasonic welding reduces energy costs (no consumables), eliminates shielding gas, and operates at lower voltages (AC220V), saving 30-50% in long-term expenses.

Why is my ultrasonic metal welder producing inconsistent weld joints?

Check for misaligned tooling, uneven pressure, or frequency drift. Calibrate welding time (0.01s-10s range) and verify energy output (1ws-9999ws).

How does system frequency (20kHz vs. 40kHz) affect weld strength in ultrasonic machines?

Lower frequencies (20kHz-30kHz) provide deeper penetration for thick metals, while 40kHz offers precision for thin, delicate components.

What safety standards should be followed when operating high-power (10,000W) ultrasonic welders?

Use PPE, secure grounding (AC380V input), ensure proper machine weight (160KG stability), and install vibration-dampening mounts.