What Is Ultrasonic Food Cutting

Ultrasonic food cutting is a process of using ultrasonic to easily separate food. This technology converts electrical energy into ultrasonic waves through an ultrasonic transducer, which are then conducted to the ultrasonic knife to induce high-frequency vibrations. When the blade comes into contact with food, the high-frequency vibrations and cavitation effect of the ultrasonic knife are utilized to achieve efficient cutting. Ultrasonic cutting minimizes the problems of food sticking to the knife and high cutting resistance, and meets food-grade cleanliness standards, making it highly suitable for large-scale batch production.

What foods are suitable for ultrasonic cutting?

- 1. Sticky or Soft Foods – Chocolate: Avoids melting or sticking during cutting, maintaining a smooth surface (e.g., chocolate blocks, chocolate-coated foods). – Candies/Gummy: Such as gummy bears and marshmallows, featuring neat cutting edges without stringing.

- 2. Multi-Layered or Deformable Foods – Cakes/Desserts: Multi-layered cream cakes, cheesecakes, etc., ensuring no damage to the layered structure during cutting (e.g., layered cakes, cheesecakes). – Sandwiches/Hamburgers: Maintains shape when cutting bread or fillings, preventing extrusion (e.g., pre-made sandwiches, burger patties). – Sushi/Rolls: Such as sushi rolls and spring rolls, with flat cut surfaces and no knife sticking (e.g., sushi rolls, spring rolls).

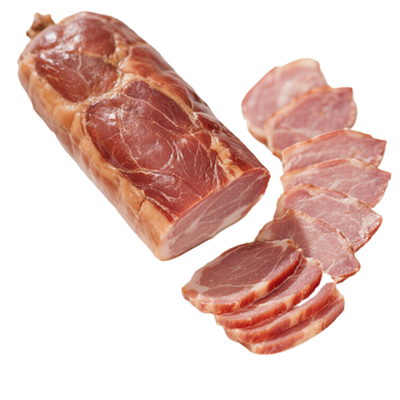

- 3. High-Moisture or Fragile Foods – Fruits/Vegetables: – Soft fruits: Mango, kiwi, strawberry (reduces juice loss during cutting). – Crisp vegetables: Cucumber, celery, carrot (keeps cut surfaces smooth and avoids fragmentation). – Cooked Meats: Such as ham and sausages, reducing crumbs during cutting (e.g., ham, sausages). – Tofu/Dairy Products: Soft tofu, cheese (maintains shape and prevents crushing).

- 4. Frozen or Hard Foods – Frozen Desserts: Ice cream, frozen cakes, etc., allowing cutting without pre-thawing. – Nuts/Hard Candies: Such as almonds and hard candy pieces, reducing crumbs and splashes during cutting.

- 5. Special Processed Foods – Coated Foods: Such as chocolate-coated cookies and frosted pastries, protecting the outer coating from peeling during cutting.

Advantages of ultrasonic food cutting

- Non-stick Blade

- Prevents food adhesion, reduces cleaning frequency, and improves production efficiency.

- Ideal for high-viscosity foods (e.g., cheese, chocolate, cakes).

- Low Cutting Resistance

- Minimizes pressure during cutting, reducing food deformation and breakage.

- Extends blade lifespan and lowers maintenance costs.

- High-Speed & Industrial Compatibility

- Fast cutting speed, integrates seamlessly into automated production lines for mass production.

- Equipped with intelligent control systems for continuous, precise cutting.

- Perfect Cutting Surface

- Smooth, tear-free edges without debris, preserving food shape integrity.

- Reduces product waste and enhances visual appeal for market competitiveness.

Hyusonic Food Cutting Machine

contact us for ultrasonic welding solutions

Fill up the Form and Ask Your Queries

Address

No. 168 Weita Road, Zhangpu Town , Kunshan , Suzhou , Jiangsu , China

Phone/WhatsApp

+(86) 13776317970

rui.zhang@hyusonic.com

hyusonic2009@gmail.com

Why HYUSONIC is Trusted by 5000+ Clients

- Professional Technical Support : 20 years of ultrasonic welding expertise guarantees 100% feasibility assessment for your product's welding needs.

- Thousands of Welding Experiences : With experience serving 5,000+ global clients and welding expertise across 1,000+ product types, we deliver accurate, complete welding solutions for your specific needs.

- German Technology : Hyusonic originated as a German OEM and has established deep technical cooperation with Germany's leading ultrasonic welding experts. We hold ISO 9001, CE certifications, and multiple patents, ensuring premium quality and innovation.