How Ultrasonic Welding Works for ABS Plastic

Publish Data:2025.7.15 Author: Hyusonic

Can ABS plastic be welded? Absolutely. As a popular thermoplastic, ABS (Acrylonitrile Butadiene Styrene) is widely used in industries like automotive, electronics, and consumer goods due to its strength, impact resistance, and ease of molding. Welding ABS plastic is not only possible but also essential for joining parts efficiently. Among various methods, ultrasonic welding stands out as a top choice for its speed, precision, and reliability.

What Is Ultrasonic Welding for ABS?

Advantages of Ultrasonic Welding for ABS Plastic

- Speed and Efficiency

Ultrasonic welding ABS plastic is incredibly fast. Most welds are completed in 0.5 to 2 seconds, making it perfect for high-volume production lines. Unlike adhesive bonding or mechanical fastening, there’s no waiting time for curing or assembly, which boosts productivity.

- Strong and Reliable Bonds

The welds created through ABS plastic welding using ultrasonic technology are often as strong as the original material. The heat is localized at the joint, so the surrounding plastic remains undamaged, preserving the part’s structural integrity.

- Clean and Consistent Results

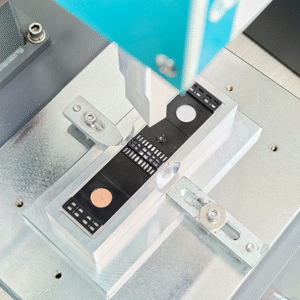

Ultrasonic welding produces clean welds with no need for additional materials like glue or screws. This eliminates the risk of contamination and ensures consistent quality across all parts. The process is highly repeatable, making it suitable for precision applications like electronics enclosures.

- Cost-Effective

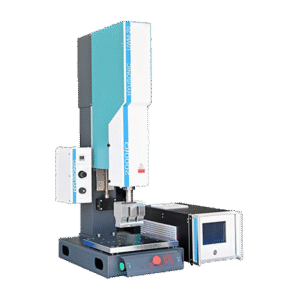

While the initial investment in an abs plastic welder may be higher than some methods, ultrasonic welding saves money in the long run. It reduces material waste, lowers labor costs, and minimizes rework due to its high success rate.

Welding ABS with Composite Additives

- Glass fiber-reinforced ABS may require slightly higher amplitude or pressure to ensure the plastic melts around the fibers.

- Carbon fiber composites, which conduct heat well, need careful tuning to avoid overheating the joint.