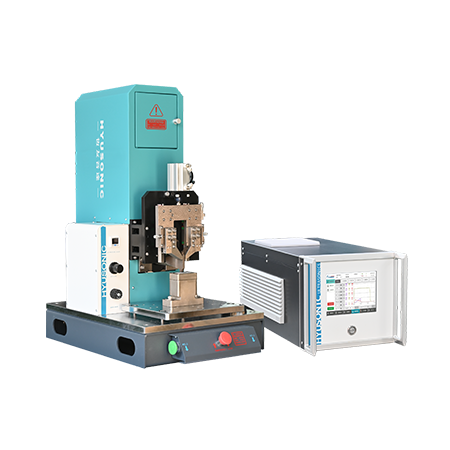

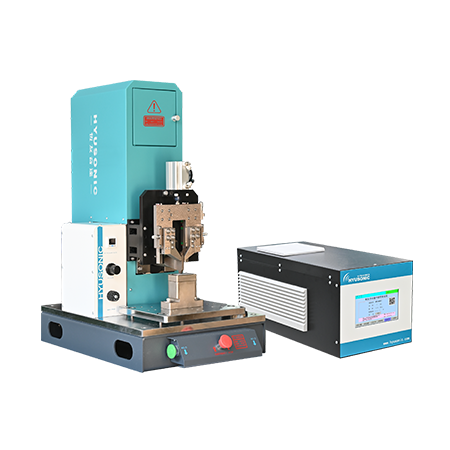

ultrasonic metal welder ST series

-

Digital Ultrasonic System

Components Precision-engineered with high-performance acoustic parts . -

Full-Series Modular Design

Scalable configurations for diverse production needs. -

CE & ISO 9001 Certified

Compliant with EU Machinery Directive and global quality standards for risk-free global deployment. -

Quality Control Window

Set time threshold to control welding quality

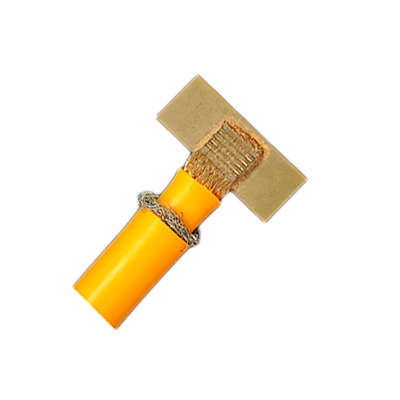

description

The ST series ultrasonic metal welding machines feature automatic identification alarm, automatic frequency tracking & searching, and pre-vibration dropping functions. They can control welding quality based on upper and lower limits of time protection, providing a guarantee for welding quality control.

Why Choose ultrasonic metal welder ST series

Intelligent Monitoring System

Equipped with professionally designed automatic welding monitoring, defective product detection, multiple welding modes, it meets the requirements of most welding scenarios.

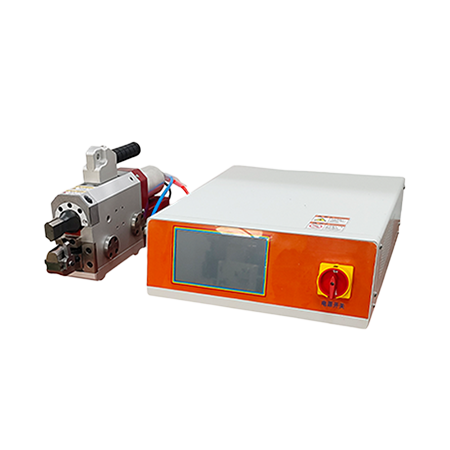

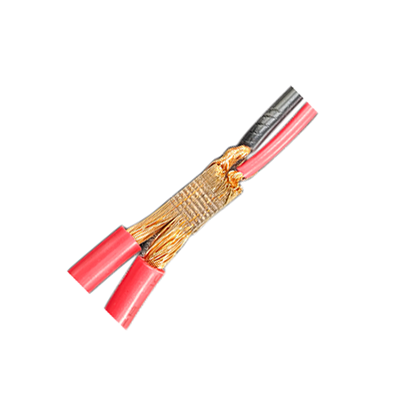

Stable Ultrasonic System

The ST series ultrasonic metal welding machine adopts a well-designed structure and a stable ultrasonic system, which is specially used for metal wire splicer, metal plate welding, battery welding and the welding is fast, clean and stable.

Price & Service

HYUSONIC, a Chinese ultrasonic welding machine manufacturer, ensures first-tier quality via excellent supply chains at favorable prices, offering comprehensive trial welding, training, warranty and after-sales support.

Technical data

| Category | Parameter | Specifications/Range |

|---|---|---|

| Technical Data | Frequency | 20kHz / 28kHz / 30kHz / 35kHz / 40kHz |

| Input Voltage | 220V ±10%, 50/60Hz (single-phase) | |

| Output Power | 800W / 1200W / 2000W / 2500W / 3000W / 3600W / 4000W / 4500W / 5000W / 6000W / 10000W | |

| Welding (Range/Precision) | Energy Range | 1ws – 9999ws |

| Welding Precision | 0.01mm | |

| Welding Time | Range: 0.01s – 10s | |

| Drive Requirements | Pressure | 2000-5000N (customizable) |

| Stroke | 20-50mm (customizable) | |

| Dimensions | Frame (W×D×H) | 350mm × 550mm × 1280mm |

welding cases

Customer FAQs

What is the difference with international first-line brands?

What are the cost benefits of switching from laser welding to ultrasonic metal welding?

Ultrasonic welding reduces energy costs (no consumables), eliminates shielding gas, and operates at lower voltages (AC220V), saving 30-50% in long-term expenses.

Why is my ultrasonic metal welder producing inconsistent weld joints?

Check for misaligned tooling, uneven pressure, or frequency drift. Calibrate welding time (0.01s-10s range) and verify energy output (1ws-9999ws).

How does system frequency (20kHz vs. 40kHz) affect weld strength in ultrasonic machines?

Lower frequencies (20kHz-30kHz) provide deeper penetration for thick metals, while 40kHz offers precision for thin, delicate components.

What safety standards should be followed when operating high-power (10,000W) ultrasonic welders?

Use PPE, secure grounding (AC380V input), ensure proper machine weight (160KG stability), and install vibration-dampening mounts.