Optional Configurations

- Servo-Driven Precision Control

- MES Integration (Industry 4.0 Ready)

- Automated Load/Unload Systems

- Vision-Based Inspection & Recognition

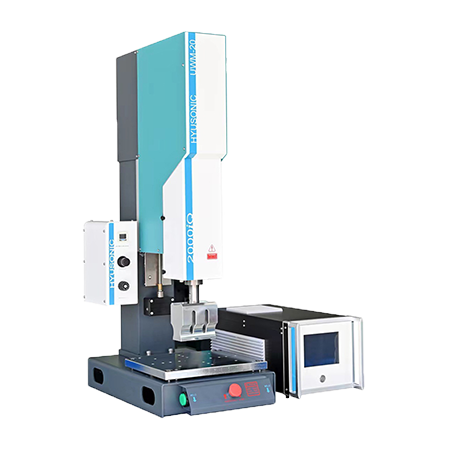

ultrasonic plastic welding machine x series

-

Full-Series Modular Design

Plug-and-Play Modularity: Rapid tooling swap (<10 mins) and scalable configurations for multi-product workflows. -

CE & ISO 9001 Certified

Compliant with EU Machinery Directive 2006/42/EC and global quality standards for risk-free global deployment. -

6 Welding Modes & 4 Trigger Modes

Welding Logic: Time, Energy, Peak Power, Absolute/Relative Distance/Ground Detect.

Triggers: Time, Pressure, Position, Power – adapts to complex automation sequences. -

Real-Time Monitoring & Quality Assurance

Dynamic Data Tracking: Live graphs for time, displacement, pressure, and power.

Smart Threshold Alerts: Auto-stop on parameter deviations.

USB Data Export: Securely transfer welding logs (CSV/Excel) for traceability and AI-driven analysis.

description

The Hyusonic ultrasonic plastic welding machine X series, fully German-engineered, delivers unmatched stability and precision for mission-critical industries like medical devices and aerospace. Featuring ultra-rigid components and ±0.01mm tolerance control, it achieves zero-defect welds under extreme conditions. With seamless Industry 4.0 integration and >95% energy efficiency, it’s the gold standard for high-value production.

The X-series ultrasonic plastic welding machines, like the iQ series, feature the same quality inspection, quality control management, and automatic defective product monitoring and alarm systems. They ensure the precision of welded products through multi-dimensional control via various triggering modes, strictly adhere to welding output standards, and significantly enhance the yield rate and product uniformity.

Why X series Stand Out

100% German Ultrasonic System

We have in-depth technical cooperation with Germany and use 100% components of ultrasonic systems that meet international standards to ensure the stability and quality of the machines.

Latest Control Technology

The X series ultrasonic plastic welding machines feature intelligent QC monitoring/alarm, Industry 4.0 integration, and multi-dimensional threshold control for 0.01mm precision, meeting medical-grade and high-quality inspection standards.

Price & Service

HYUSONIC, a Chinese ultrasonic welding machine manufacturer, ensures first-tier quality via excellent supply chains at favorable prices, offering comprehensive trial welding, training, warranty and after-sales support.

advantages of ultrasonic plastic welder x Series

Original Imported Digital Ultrasonic System

Advanced digital control ensures precision and reliability.

Password-Protected Login & Bilingual Interface

Role-based access control (Chinese/English language options) for enhanced operational security.

Six Programmable Welding Modes

Time/Energy/Peak Power/Absolute Distance/Relative Distance/Ground Detect – Adapts to diverse materials (plastics, composites, metals).

Four Trigger Modes for Precision Control

Time/Pressure/Position/Power Triggers – Enables flexible process integration.

Intelligent Quality Assurance

Real-Time Welding Curve Display: Tracks time, displacement, pressure, and power data.

Smart Threshold Monitoring: Auto-alerts for parameter deviations (time/energy/power/pressure limits).

Color Touchscreen + USB Data Export: Records all parameters for traceability and PC analysis.

Adjustable Amplitude (10%-100%) with Advanced Functions

Vibration Drop & Pre-Vibration Settings – Reduces flash and optimizes weld consistency.

Auto Frequency Tracking & Electronic Pressure Measurement

Compensates for tooling wear and ensures ±1% pressure accuracy.

Ethernet Connectivity & Recipe Management

Optional Network Integration: Remote monitoring and data storage via Ethernet.

1000+ Preset Welding Recipes: Rapid job switching for batch production.

Ultra-Efficient Transducer & Rigid Titanium Booster

High-Efficiency Transducer: >95% electro-mechanical conversion rate.

Optimized Resonance System: Minimal energy loss and ±0.5% amplitude stability.

Digital Multi-Stage Pressure/Amplitude Control

5-Stage Programmable Profiles: Enables complex welding sequences.

Technical data

| Parameter | Specification/Value | |

|---|---|---|

| Technical Data (HYU750X) | Frequency | 28kHz / 30kHz / 35kHz / 40kHz |

| Input Voltage | 220V AC ±10%, 50/60Hz, Single-phase | |

| Input Current | 6A (Max, at full load) | |

| Output Power | 800W / 1200W | |

| Welding Performance | Energy Range | 1Ws – 9999Ws |

| Adjustable Displacement Accuracy | ±0.01mm | |

| Welding Time Range | 0.01s – 10s (Precision: 1ms) | |

| Drive Requirements | Pressure | 750N |

| Stroke | 75mm (Customizable) | |

| Physical Specifications | Frame Dimensions (W×D×H) | 400mm × 700mm × 1450mm |

welding cases

What Our Clients Say

Customer FAQs

How much does an industrial plastic ultrasonic welder cost?

The price of ultrasonic welding machine depends on the component structure of ultrasonic system, welding requirements and precision to be achieved. The general price ranges from several thousand to hundreds of thousands. If you need ultrasonic welding equipment, choose hyusonic to request a quote.

How fast is ultrasonic plastic welding vs hot plate welding?

Ultrasonic welding is 3-5x faster (typical cycle time 0.2-2s vs 10-30s).

How to choose between 20kHz and 40kHz for plastic welding?

20kHz: Better for thick parts (5-10mm) like automotive bumpers

40kHz: Ideal for thin/delicate plastics (0.5-3mm) like medical devices

Can ultrasonic welders join dissimilar plastics?

Yes, but only compatible pairs (e.g., ABS to PC). Use our Material Compatibility Calculator to verify your combination.

What plastics can be welded with an ultrasonic welder?

Our ultrasonic welders are compatible with ABS, PP, PVC, Nylon, PET, and HDPE. For materials like PTFE or LDPE, contact us for customized solutions.