Can PVC Be Ultrasonically Welded? A Comprehensive Guide

Publish Data:2025.7.10 Author: Hyusonic

Polyvinyl chloride (PVC) stands as one of the most widely used thermoplastics across industries, but many manufacturers wonder: can PVC be effectively joined using ultrasonic welding? The answer is a resounding yes. In this detailed guide, we’ll explore the science behind ultrasonic PVC welding, its advantages over traditional methods, and how to achieve optimal results with this versatile technique.

Before diving into welding processes, it’s critical to understand what makes PVC compatible with ultrasonic techniques. PVC (both rigid and flexible varieties) is a thermoplastic, meaning it softens when heated and hardens when cooled—this property is essential for any welding method. Key characteristics that enable successful ultrasonic welding include:

Melting Range: PVC typically melts between 160°C and 210°C (320°F–410°F), a range easily achievable with ultrasonic energy without causing material degradation.

Molecular Structure: The polymer chains in PVC allow for interdiffusion when softened, creating strong bonds at the weld interface.

Density and Rigidity: Rigid PVC (uPVC) offers sufficient structural stability to transmit ultrasonic vibrations, while flexible PVC (containing plasticizers) can be welded with adjusted amplitude settings.

These properties make PVC an ideal candidate for ultrasonic welding, provided the right equipment and parameters are used.

Common PVC Welding Challenges (and How Ultrasonic Solves Them)

Traditional PVC joining methods come with significant drawbacks that ultrasonic welding addresses:

Solvent Welding: Uses toxic chemicals (like tetrahydrofuran) that pose health risks and require ventilation. It also has long curing times (24+ hours) and weakens in high-moisture environments.

Hot Plate Welding: Creates excessive heat-affected zones (HAZ), leading to brittleness. It’s slow (cycle times of 10+ seconds) and struggles with complex geometries.

Mechanical Fastening: Leaves gaps that cause leaks, adds weight, and increases assembly time.

Ultrasonic welding eliminates these issues by using high-frequency vibrations (20–40 kHz) to generate localized heat at the joint interface. This focused energy melts the PVC surface, creating a molecular bond as the material cools—no solvents, long wait times, or gaps involved.

Ultrasonic Welding vs. Other PVC Welding Methods

Method | Setup Time | Cycle Time | Bond Strength | Environmental Impact | Best For |

Ultrasonic Welding | Low | 0.1–1 sec | High | Eco-friendly | Precision parts, medical devices |

Solvent Welding | Medium | 24+ hrs | Medium | Toxic fumes | Large pipes, non-critical joints |

Hot Plate Welding | High | 10–30 sec | Medium-high | High energy use | Large flat surfaces |

Mechanical Fastening | Medium | 5–15 sec | Low | Waste from fasteners | Temporary assemblies |

How to Achieve Perfect Ultrasonic Welds on PVC

Success with ultrasonic PVC welding depends on three key factors: equipment setup, joint design, and process parameters.

1. Equipment Selection

Ultrasonic Welder: Choose a machine with adjustable frequency (20 kHz for thick rigid PVC, 40 kHz for thin or flexible PVC). A 1500–3000 watt unit works for most applications.

Fixtures: Secure the PVC part with a rigid anvil that mirrors the horn’s shape, preventing part distortion during welding.

2. Joint Design Tips for PVC

Energy Director: Add a small raised ridge (0.2–0.5mm) on one surface to focus ultrasonic energy, reducing HAZ and improving bond strength.

Shear Joints: Ideal for rigid PVC—creates a overlapping edge that melts uniformly, perfect for leak-proof seals (e.g., medical tubing).

Butt Joints: Suitable for flexible PVC, paired with a clamp to maintain pressure during welding.

3. Optimal Process Parameters

Amplitude: 20–50μm for rigid PVC; 50–100μm for flexible PVC (plasticizers require more vibration).

Pressure: 20–50 psi (adjust based on part thickness—thicker parts need higher pressure).

Weld Time: 50–200 milliseconds (longer times risk burning; shorter times cause weak bonds).

Welding PVC Composites: Handling Mixed Materials

Many modern products use PVC composites (e.g., PVC-aluminum laminates in packaging, PVC-ABS blends in automotive parts). Ultrasonic welding excels here by:

Selective Heating: Targets the PVC layer while leaving other materials (like aluminum) unaffected, preventing delamination.

Surface Preparation: Plasma treatment of composite surfaces removes contaminants and increases PVC’s surface energy, improving adhesion.

Controlled Energy: Digital ultrasonic welders (e.g., Herrmann or Branson models) adjust power in real time to accommodate varying material thicknesses.

A common example is medical blister packs, where ultrasonic welding joins PVC sheets to aluminum foil, creating a sterile seal that resists punctures and chemical exposure.

Real-World Applications of Ultrasonic PVC Welding

Medical Devices: Welding PVC IV bags and blood collection tubes—critical for maintaining sterility and preventing leaks.

Automotive: Assembling PVC door seals and cable harnesses, where vibration resistance and weatherproofing are essential.

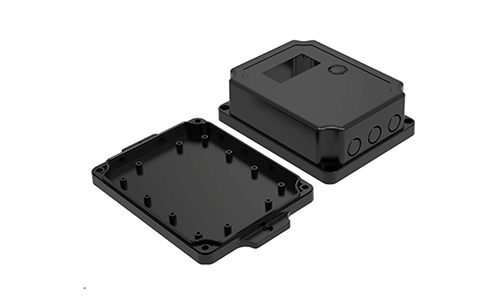

Electronics: Sealing PVC enclosures for sensors and control units, protecting against dust and moisture.

Troubleshooting Common Ultrasonic PVC Welding Issues

Weak Bonds: Increase amplitude by 5–10μm or extend weld time by 20ms. Check for contaminated surfaces.

Burn Marks: Reduce pressure or shorten weld time. Ensure the horn is properly aligned with the joint.

Part Distortion: Use a stiffer anvil or reduce clamp force. For flexible PVC, lower the frequency to 20kHz.

Inconsistent Welds: Calibrate the welder’s energy settings and inspect the horn for wear (replace if damaged).

Choosing the Right Ultrasonic Welding Equipment for PVC

Hyusonic ultrasonic PVC welding machines can weld PVC products of various shapes, sizes, and thicknesses. It offers high welding precision, no chemical contamination, and extremely fast welding speeds, enabling mass production.

This ultrasonic PVC welder boasts six welding modes and four triggering methods, far exceeding the functionality and precision of conventional two-mode welders on the market. Its stable power output and Industry 4.0 batch management weld quality make it an ideal choice for thermoplastic welding and sealing in the medical, automotive, and electronics packaging industries.

Conclusion: Ultrasonic Welding – The Future of PVC Assembly

Ultrasonic welding has revolutionized PVC joining, offering speed, strength, and sustainability that traditional methods can’t match. Whether working with pure PVC or composites, this technique delivers consistent results across industries, from medical to automotive.

By understanding PVC’s properties, optimizing equipment settings, and addressing common challenges, manufacturers can achieve reliable, high-quality welds that meet strict performance standards. As PVC continues to be a staple in manufacturing, ultrasonic welding will remain its most efficient and effective joining solution.