Optional Configurations

- Servo-Driven Precision Control

- MES Integration (Industry 4.0 Ready)

- Automated Load/Unload Systems

- Vision-Based Inspection & Recognition

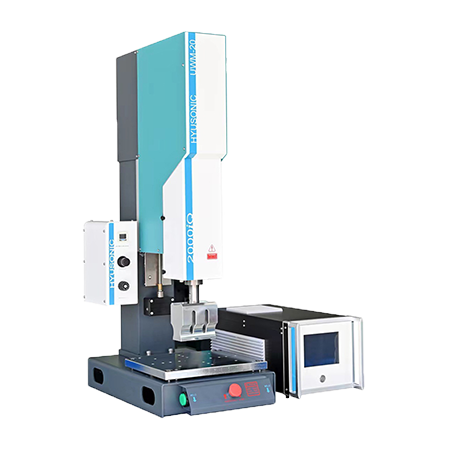

Ultrasonic Welder for Plastic – iQ Series

-

European Imported Ultrasonic Components

It adopts German imported circuit board components and rigid joint connection to achieve high-precision control and stability. -

Full-Series Modular Design

Scalable configurations for diverse production needs. -

CE & ISO 9001 Certified

Compliant with EU safety standards and international quality management. -

6 Welding Modes & 4 Trigger Modes

Programmable logic for complex applications (Time/Energy/Peak Power/Absolute Distance/Relative Distance/Ground Detect modes). -

Real-Time Monitoring & Quality Control

Dynamic data tracking (pressure/power/displacement) with automated fault alerts.

description

The HYUSONIC iQ Series is a high-end, intelligent ultrasonic welder for plastic that delivers exceptional precision and stability. Powered by HYUSONIC’s proprietary intelligent control system (SWIM™), this ultrasonic plastic welding machine offers 6 versatile welding modes and 4 flexible trigger methods to meet diverse application needs. Featuring multi-dimensional upper and lower limit synchronous control, it ensures welding accuracy with a controllable precision up to 0.01mm. Equipped with intelligent defective product monitoring and real-time welding curve display, the iQ Series guarantees consistent high-quality welds.

This precision plastic ultrasonic welder incorporates German-manufactured components and a rigidly connected acoustic system, delivering stable and reliable performance comparable to high-end ultrasonic welding machines from top-tier brands—yet at a more cost-effective price. Ideal for industries with stringent requirements such as medical device manufacturing and electronics assembly, the iQ Series combines advanced technology with excellent value.

What Is an Ultrasonic Plastic Welder?

Ultrasonic plastic welding is a high‑frequency joining method that uses mechanical vibrations and pressure for thermoplastic fusion. Unlike adhesives or hot plate welding, it delivers clean, fast, and repeatable bonds—ideal for medical device housing, electronic sensor packaging, and battery shell assembly.

Why iQ Series Stand Out

German Stable Ultrasonic System

We have in-depth technical cooperation with Germany and use important components of ultrasonic systems that meet international standards to ensure the stability and quality of the machines.

Latest Control Technology

The iQ series ultrasonic welder for plastic features intelligent QC monitoring/alarm, Industry 4.0 integration, and multi-dimensional threshold control for 0.01mm precision, meeting medical-grade and high-quality inspection standards.

Price & Service

HYUSONIC, a Chinese ultrasonic welding machine manufacturer, ensures first-tier quality via excellent supply chains at favorable prices, offering comprehensive trial welding, training, warranty and after-sales support.

Advantages of Ultrasonic Welder For Plastic

High-Performance Digital Ultrasonic System with Intelligent Control

The HYUSONIC iQ Series features a robust ultrasonic system engineered for stable energy transmission and long-term durability. It supports six programmable welding modes (Time, Energy, Peak Power, Absolute Distance, Relative Distance, and Ground Detect) and four trigger modes (Time, Pressure, Position, Power), offering flexible process control for various plastics, composites, and even metals in complex welding applications.

Intelligent Quality Assurance and Real-Time Data Monitoring

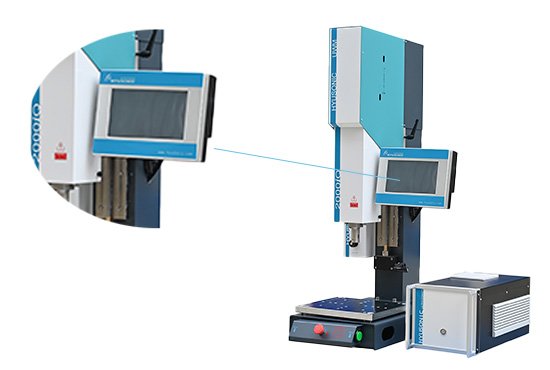

Real-time welding curve display enables dynamic monitoring of key parameters such as time, displacement, pressure, and power. Smart threshold monitoring provides automatic alerts for any deviations, ensuring consistent weld quality. A color touchscreen with USB data export ensures complete traceability and facilitates PC-based analysis.

Energy Efficiency and Network Connectivity

The adjustable amplitude range (10%–100%) combined with pre-vibration and amplitude drop functions reduces flash and improves weld consistency. Auto frequency tracking and electronic pressure sensing compensate for tooling wear, delivering pressure accuracy of ±1%. With a high-efficiency transducer (>95% conversion rate) and rigid titanium booster, the system minimizes energy loss and ensures amplitude stability within ±0.5%. Ethernet connectivity and recipe management with over 1000 preset welding programs support remote monitoring and rapid changeovers in batch production.

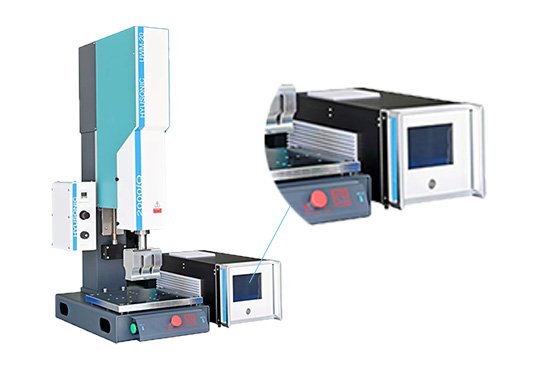

Design solutions that match your needs

Our ultrasonic welder for plastic can be customized with a humanized design according to the customer’s usage habits and environment. Movable operation display screen and electric box operation screen are optional. It also includes desktop and floor-standing designs to provide convenience for different operating environments.

Technical data

| Technical Data | Specifications |

|---|---|

| Machine Power | 800W / 1200W / 2000W / 2500W / 3000W / 3600W / 4000W / 5000W / 10000W |

| System Frequency | 15kHz / 20kHz / 28kHz / 30kHz / 35kHz / 40kHz |

| Power Input | AC 220V ±10%, 50Hz/60Hz |

| Pressure | 2000-5000N(Customizable) |

| Welding Stroke | 75mm / 100mm (Customizable stroke available) |

| Operation Type | Desktop Type / Floor-standing Integrated Type |

| Weight | 55kg / 160kg |

| Welding (Range/Accuracy) | Range: 1ws–9999ws |

| Adjustable Displacement Accuracy: 0.01mm | |

| Welding Time | Range: 0.01s–10s |

| Dimensions | Frame (L×W×H): 370mm × 600mm × 1115mm |

| Electrical Box (W×D×H): 265mm × 580mm × 255mm |

welding cases

What Our Clients Say

Customer FAQs

How much does an industrial plastic ultrasonic welder cost?

The price of an ultrasonic welding machine depends on the component structure of the ultrasonic system, welding requirements, and the precision to be achieved. The general price ranges from several thousand to hundreds of thousands. If you need ultrasonic welding equipment, choose Hyusonic to request a quote.

How fast is ultrasonic plastic welding vs hot plate welding?

Ultrasonic welding is 3-5x faster (typical cycle time 0.2-2s vs 10-30s).

How to choose between 20kHz and 40kHz for plastic welding?

20kHz: Better for thick parts (5-10mm) like automotive bumpers

40kHz: Ideal for thin/delicate plastics (0.5-3mm) like medical devices

Can ultrasonic welders join dissimilar plastics?

Yes, but only compatible pairs (e.g., ABS to PC). Use our Material Compatibility Calculator to verify your combination.

What plastics can be welded with an ultrasonic welder?

Our ultrasonic welders are compatible with ABS, PP, PVC, Nylon, PET, and HDPE. For materials like PTFE or LDPE, contact us for customized solutions.