What Is Ultrasonic Welding Metal

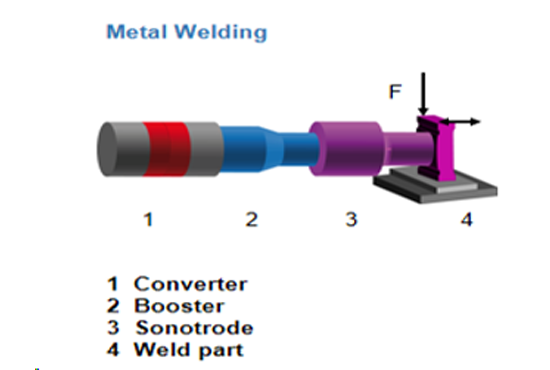

The ultrasonic welding process is well suited for welding metals. Ultrasonic metal welding is a process where an ultrasonic welding machine generates high-frequency mechanical vibrations, causing the metal surface to heat up while applying pressure. This disrupts the oxide layer on the metal surface, allowing lattice diffusion and bonding between metal atoms, thus completing the welding of non-ferrous metals. Ultrasonic metal welding typically includes core components such as an ultrasonic generator(power supply), transducer(converter), booster, and welding horn(sonotrode).

Advantages of Ultrasonic Welding Metal

– High Welding Quality: Ultrasonic metal welding belongs to low-temperature solid-phase welding, avoiding problems such as tissue inhomogeneity and thermal stress caused by metal phase transformation. This enables ultrasonic metal welding to maintain the corrosion resistance, mechanical properties, and electrical conductivity of raw materials.

– Wide Application Range: Capable of welding various non-ferrous metals and alloys such as copper, aluminum, nickel, silver, etc., and can also achieve welding of dissimilar metals (e.g., copper and aluminum).

– Environmentally Friendly Process: No sparks, smoke, or harmful gases are generated during welding. Flux addition is unnecessary, making it eco-friendly.

– Precise Control: HYUSONIC metal welders support six welding modes: Time, Energy, Peak Power, Absolute Distance, Relative Distance, and Ground Monitoring. Meanwhile, they feature four triggering modes: Time, Pressure, Position, and Power. With multi-dimensional threshold adjustment and a control accuracy of 0.01mm, they achieve complete high precision and controllability.

Applications of Ultrasonic Metal Welding

- Electronics & Electrical Appliances:

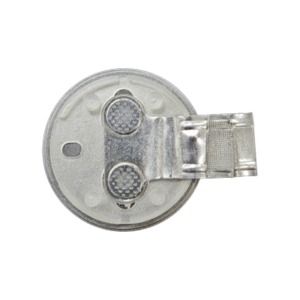

- Welding wires, cables, terminals, contacts, and microelectronic components, such as smartphone battery connectors and internal computer circuit connections.

- Automotive Manufacturing:

- Welding battery tabs, motor windings, sensor components, and automotive electronic circuits. Specifically in power battery production, it is used for welding battery electrodes, busbars, and module connectors.

- Aerospace:

- Welding precision metal components in aerospace equipment, including sensors and electronic elements.

What Material Can Be Ultrasonic Welded

- Copper-aluminum: Welding of power battery tabs and heat dissipation modules (requires controlling the thickness of intermetallic compounds at the interface);

- Aluminum-nickel: Connection of lithium battery electrode sheets and nickel strips;

- Copper-silver: Welding of high-conductivity contacts;

- Titanium-stainless steel: Welding of corrosion-resistant components for medical equipment.

can you ultrasonic weld metal to plastic

Ultrasonic welding can only achieve the joining of a small portion of plastics and metals, and is only suitable for low-strength, non-critical load-bearing scenarios. This is because plastics and metals cannot form chemical bonds through atomic diffusion, and can only be connected through physical adsorption or interfacial interlocking, with strength far lower than that of welding the same material. Additionally, it is necessary to meet conditions such as thermoplastic plastics + soft metals + surface pretreatment + intermediate layer materials. For some applications, using ultrasonic riveting and embedding(a variant of ultrasonic welding), plastics and metals can be firmly joined together.

can you ultrasonic weld metal to metal

Yes. Ultrasonic welding can join different metals together, such as copper and aluminum, while still maintaining excellent electrical conductivity. For non-ferrous metal materials that need to be welded according to different application requirements, it is feasible to try welding and ensure the weldability.

Comparison with Resistance and Laser Welding

Ultrasonic welding for metal offers distinct advantages over resistance and laser welding. Unlike resistance welding, it requires no high current, reducing energy consumption and eliminating electrode wear. Compared to laser welding, ultrasonic welding is safer, generates less heat, and requires no complex optics or shielding gas. It’s ideal for joining thin, conductive, non-ferrous metals like copper and aluminum. With faster cycle times and lower operating costs, ultrasonic metal welding is especially suited for battery tabs, wire terminals, and electronics. Its solid-state nature ensures clean, reliable joints without melting or spatter.

Ultrasonic Welding Metal Video

More Principles of Ultrasonic Welding

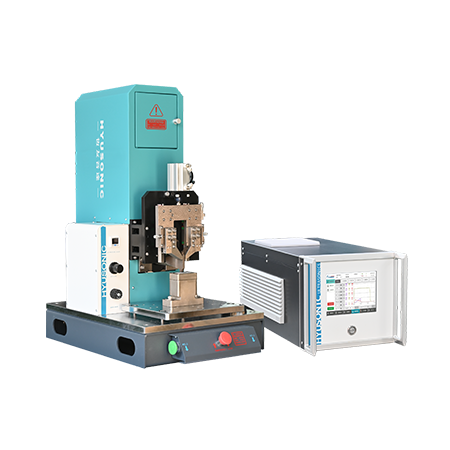

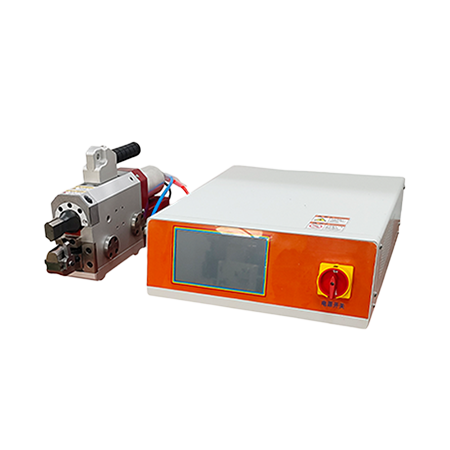

Hyusonic Ultrasonic Metal Weder

Ultrasonic metal welding can be used for welding non-ferrous metal wire harnesses, non-ferrous metal sheets, terminal welding, and metal tube sealing.

contact us for ultrasonic welding solutions

Fill up the Form and Ask Your Queries

Address

No. 168 Weita Road, Zhangpu Town , Kunshan , Suzhou , Jiangsu , China

Phone/WhatsApp

+(86) 13776317970

rui.zhang@hyusonic.com

hyusonic2009@gmail.com

Why HYUSONIC is Trusted by 5000+ Clients

- Professional Technical Support : 20 years of ultrasonic welding expertise guarantees 100% feasibility assessment for your product's welding needs.

- Thousands of Welding Experiences : With experience serving 5,000+ global clients and welding expertise across 1,000+ product types, we deliver accurate, complete welding solutions for your specific needs.

- German Technology : Hyusonic originated as a German OEM and has established deep technical cooperation with Germany's leading ultrasonic welding experts. We hold ISO 9001, CE certifications, and multiple patents, ensuring premium quality and innovation.