Advantages and Disadvantages of Ultrasonic Welding

Publish Data:2025.8.6 Author: Hyusonic

Exploring the Key Benefits and Limitations in Modern Manufacturing

1. Introduction to Ultrasonic Welding

Ultrasonic welding is a highly efficient, clean, and precise joining technology widely used in various industries such as automotive, medical, electronics, and packaging. Unlike traditional methods involving heat or adhesives, ultrasonic welding utilizes high-frequency acoustic vibrations to generate frictional heat at the joint interface of thermoplastics or metals.

This non-invasive, energy-efficient process is gaining prominence in applications where speed, cleanliness, and reliability are essential. However, like any technology, ultrasonic welding has its own set of advantages and challenges.

In this article, we’ll dive deep into what makes ultrasonic welding so advantageous, what critical disadvantages manufacturers should be aware of, and how it compares with other joining methods in the industrial world.

2. How Ultrasonic Welding Works

Before exploring the pros and cons, it’s essential to understand the basics:

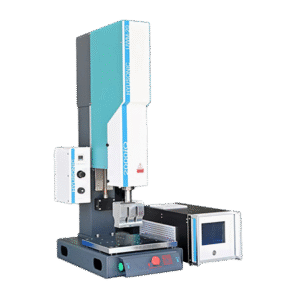

Ultrasonic welding machine components:

Generator (power source)

Converter/transducer

Booster

Sonotrode (horn)

Anvil or fixture

The Process:

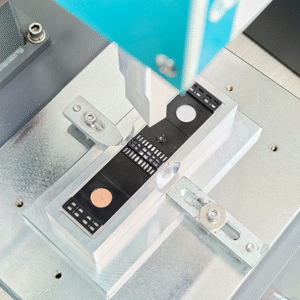

The components to be welded are placed under pressure.

The ultrasonic welder emits high-frequency (20 kHz – 40 kHz) vibrations.

Vibrational energy is concentrated at the joint via an energy director or interface point.

Localized heat melts the plastic or softens metal for fusion.

Pressure is maintained during cooling to create a solid bond.

This quick, non-invasive method eliminates the need for adhesives, bolts, or external heat.

3. What Are the Advantages of Ultrasonic Welding?

Ultrasonic welding brings a multitude of operational and economic benefits.

3.1 High Speed and Productivity

One of the most celebrated advantages is rapid welding speed. A single weld cycle typically takes less than one second.

Ideal for high-throughput production lines.

No curing or drying time required (unlike adhesives).

Fully automated using robotic arms and PLC systems.

🔑 Example: In medical device manufacturing, ultrasonic plastic welders are used for assembling filters, IV catheters, and syringes in milliseconds.

3.2 Clean and Eco-Friendly

No solvents, adhesives, or consumables needed.

Leaves no residues or contaminants, essential for sterile environments.

Reduces material waste significantly.

🔬 Ultrasonic welding is preferred in cleanroom settings such as the pharmaceutical or electronics industry due to its hygienic operation.

3.3 Strong and Precise Bonds

Suitable for micro-scale and precision components.

Guarantees repeatable and homogeneous welds.

No distortion or thermal damage to surrounding parts.

🔧 Example: Ultrasonic welding machines are capable of bonding delicate electronic circuits without damaging microchips.

3.4 Energy Efficiency

Requires much less energy compared to hot plate welding or laser welding.

Energy is delivered only where it’s needed.

📊 Studies show ultrasonic welders can consume up to 80% less energy than traditional heating systems.

3.5 Non-Destructive to Materials

Does not change material properties significantly.

Excellent for thin or fragile plastics (e.g., PP, ABS, PMMA).

🔄 Ultrasonic plastic welding preserves integrity in lightweight automotive parts like dashboards or air ducts.

3.6 Broad Material Compatibility

Especially effective for:

Thermoplastics: PE, PP, ABS, PC, PMMA

Non-ferrous metals (in ultrasonic metal welding): aluminum, copper

Suitable for dissimilar plastics in some configurations.

3.7 Automation-Friendly

Easily integrated into automated production lines.

Compatible with robotics, conveyors, and smart sensors.

🧠 Smart ultrasonic welding systems can adapt weld parameters in real-time for consistent quality control.

3.8 Minimal Maintenance

No need for lubrication or thermal control systems.

Most ultrasonic welding machines have long tool lives and low wear rates.

4. What Is a Big Disadvantage of Ultrasonic Welders?

Despite its many advantages, ultrasonic welding does present some limitations.

4.1 Limited to Small or Medium Parts

Not suitable for large-scale welds (e.g., large plastic housings or sheets).

Weld area is typically confined to a few centimeters.

❌ Example: For joining large automotive bumpers or panels, vibration welding or laser welding may be more suitable.

4.2 Requires Precise Joint Design

- Successful welding often depends on joint geometry:

- Energy directors must be properly designed.

- Flatness and tolerances must be tightly controlled.

🔍 A poorly designed joint may result in weak or incomplete welds.

4.3 High Initial Investment

Entry-level ultrasonic welding machines can cost thousands of dollars.

Advanced systems for metal welding (e.g., copper tab welding) can be even more expensive.

💸 This makes it challenging for small manufacturers to adopt without ROI planning.

4.4 Material Limitations

Not suitable for thermoset plastics or very thick materials.

Some composite plastics may not respond well to ultrasonic energy.

4.5 Noise and Safety

Ultrasonic frequencies (20–40 kHz) may emit high-pitched noise, potentially harmful in close proximity.

Sound enclosures and hearing protection are often required.

4.6 Operator Skill & Setup Complexity

While machines are automated, initial setup and tuning require expertise.

Sonotrode design and alignment are critical for repeatability.

5. Use Cases by Industry

Automotive

Instrument panels

Filter assemblies

Air ducts

Medical

Disposable products

Fluid control valves

Drug delivery systems

Electronics

Sensors

Housings

Microcircuit packaging

6. How to Choose the Right Ultrasonic Welder

When evaluating ultrasonic welders, consider:

Material type and thickness

Weld geometry and strength

Production volume

Automation needs

🔍 Tip: For plastic joining, ensure your ultrasonic plastic welding machine supports adjustable amplitude, force, and time settings.

7. Conclusion

Ultrasonic welding offers a compelling combination of speed, precision, and cleanliness that makes it a leading choice in modern manufacturing. While it isn’t suitable for every application, its advantages far outweigh its disadvantages in most small-to-medium part assembly contexts. Choosing the right ultrasonic welding machine and designing appropriate joints are essential to maximizing performance.

Contact Hyusonic for a free trial welding of your sample. We have 21 years of industry experience and have rich experience in solving different materials and cases.