Ultrasonic Welding: A Deep Dive into the Full Wave vs. Semi-wave Distinction (The Ultimate Guide)

Publish Data:2025.8.8 Author: Hyusonic

Introduction

In the field of ultrasonic welding, choosing the right tool is paramount to project success. However, many engineers and technicians are often perplexed by the concepts of “Full Wave” and “Semi-wave” horns and blades. While both designs are rooted in the same principles of ultrasonic physics, they exhibit fundamental differences in energy transfer patterns, appearance, application scenarios, and market prevalence. This article will thoroughly explore the physical principles behind full wave and semi-wave designs, analyze their unique characteristics, and provide a practical guide to help you make informed decisions.

Part 1: The Core Principles of Ultrasonic Welding—Wavelength and Resonance

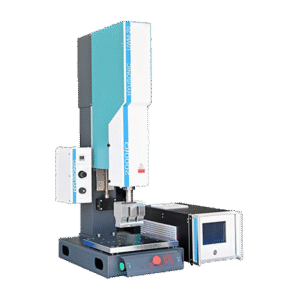

Ultrasonic welding achieves molecular friction and heat generation by applying high-frequency mechanical vibrations (typically between 20kHz and 40kHz) to thermoplastic materials. For this energy transfer to be efficient, the ultrasonic horn must achieve a state of resonance.

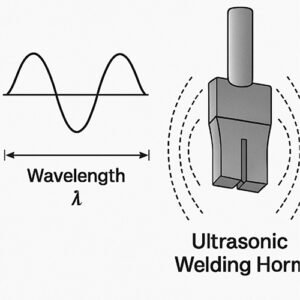

What is Wavelength?

The wavelength (λ) is the distance an ultrasonic wave travels during one complete oscillation cycle. This distance is determined by the speed of sound (C) in the material and the frequency (f), following the formula: λ = C / f. In ultrasonic welding, the physical length of the horn must be a precise multiple of the wavelength at its operating frequency to generate stable vibrations and achieve resonance.

The Significance of Resonance

When the horn’s length perfectly matches the wavelength, a standing wave is formed within the horn. A standing wave has a specific amplitude distribution pattern: at certain points, the vibration is at its maximum (known as an antinode), while at other points, the vibration amplitude is zero (known as a node). This specific amplitude distribution is what fundamentally distinguishes full wave from semi-wave designs.

Part 2: The Essential Physical Differences between Full Wave and Semi-wave

1. Semi-wave Horns

Physical Design: A semi-wave horn’s physical length is equal to half a wavelength (L = λ / 2).

Vibration Pattern: In this design, one end of the horn, which connects to the transducer, is engineered to be a node with zero amplitude. The other end, the working face, is engineered to be an antinode, where the amplitude reaches its maximum.

Energy Transfer: Energy is concentrated at a single point of the horn and transferred to the workpiece through this unique maximum-amplitude region. This “single-end focus” makes it ideal for applications requiring precise positioning and high energy density.

2. Full Wave Horns

Physical Design: A full wave horn’s physical length is equal to one full wavelength (L = λ).

Vibration Pattern: In this design, both ends of the horn are engineered to be antinodes with maximum amplitude. A single node with zero amplitude is formed in the exact middle of the horn.

Energy Transfer: A full wave horn can apply energy simultaneously from both ends. This gives it a distinct advantage in applications that require a long weld line or a large-area weld with uniform energy distribution.

Part 3: A Deep Dive into Appearance, Physical Characteristics, and Applications

1. Visual and Physical Characteristics of Horns and Blades

| Characteristic | Semi-wave Horn | Full Wave Horn/Blade |

| Length | Shorter, typically half a wavelength | Longer, typically a full wavelength |

| Structure | Asymmetrical, one end for connection, one for work | Symmetrical, both ends for work |

| Amplitude Distribution | Maximum at one end, zero at the other | Maximum at both ends, zero in the middle |

| Resonance Points | One antinode, one node | Two antinodes, one node |

| Typical Appearance | Cylindrical, stepped, small | Long bar, rectangular, elongated |

2. Core Applications and Industry Examples

Applications of Semi-wave Horns:

Automotive: Spot welding interior trim, riveting plastic clips.

Medical: Welding medical device housings, tubes, and filter membranes.

Electronics: Sealing electronic component housings and battery packs.

Consumer Goods: Riveting toy parts, sealing packaging.

Advantage: Due to their highly concentrated energy, semi-wave horns are perfect for scenarios requiring fast, precise, and small-area bonding.

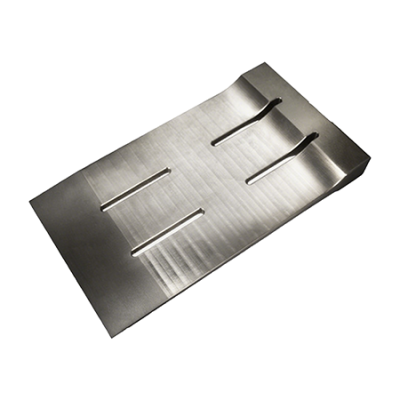

Applications of Full Wave Horns/Blades:

Food Cutting: Utilizing the high amplitude at both ends of a full wave blade to achieve smooth, non-stick cutting of cakes, cheese, and bread.

Non-woven Fabric Welding: On production lines for face masks or medical garments, a long full wave horn can be used for continuous roller welding or edge sealing.

Long-length Plastic Welding: For welding straight seams on car dashboards or large appliance casings, the full wave design ensures uniformity and strength along the entire weld line.

Advantage: The full wave design distributes vibratory energy uniformly over a longer length, making it indispensable for applications requiring large-area or long-line processing.

Part 4: A Deeper Insight—Why Are Full Wave Horns Less Common in the Market?

As you’ve observed, a search for “ultrasonic welding horns” rarely yields images of full wave designs, whereas “ultrasonic cutting blades” often feature them. This is not a coincidence; it’s a result of market demand, design challenges, and industry conventions.

Market Demand Drives Mainstream Products: The most common applications for ultrasonic welding are spot welding, riveting, and short-distance linear welding. These applications demand highly concentrated energy, a need that semi-wave horns are perfectly suited to meet. Consequently, semi-wave horns have become the “universal” and “standard” product in the market.

Challenges of Full Wave Design: A full wave horn’s longer physical length makes it more susceptible to factors like transverse vibration and thermal expansion, which can lead to resonance instability. Designing and manufacturing a full wave horn that maintains uniform, stable amplitude over a long length requires higher precision in materials and machining, resulting in higher costs.

Industry Naming Conventions: In industrial practice, the term “horn” typically refers to the smaller tool used for bonding, while “blade” or “knife” refers to the longer tool used for cutting. Since the full wave design is inherently well-suited for cutting applications that require a long working surface, the concepts of “full wave” and “blade” have become closely linked in the market.

Conclusion: Choosing the Right Tool for Exceptional Craftsmanship

The difference between full wave and semi-wave is much more than just length; it represents two distinct energy transfer modes and application philosophies. The semi-wave horn, with its concentrated energy and outstanding precision, excels in most spot welding and riveting applications. The full wave design, on the other hand, with its unique dual-end vibration pattern, proves invaluable in ultrasonic cutting and specialized welding scenarios that require a long, uniform energy distribution.

Understanding these distinctions allows you to choose the most suitable ultrasonic tool for your specific workpiece size, material properties, and process requirements, thereby significantly improving weld quality and production efficiency.